This month’s Makers are Tejas Sathe and Tom Sorrentino. Tejas and Tom are the Surgical Innovations Fellows in the UCSF Department of Surgery. Tejas is passionate about applying design thinking principles to everyday problems in healthcare and runs the ORDash project at UCSF, which aims to reduce operating room waste. Tom is heading down the physician-entrepreneur path, leading clinical development at DIATIRO, a pre-clinical stage MedTech company.

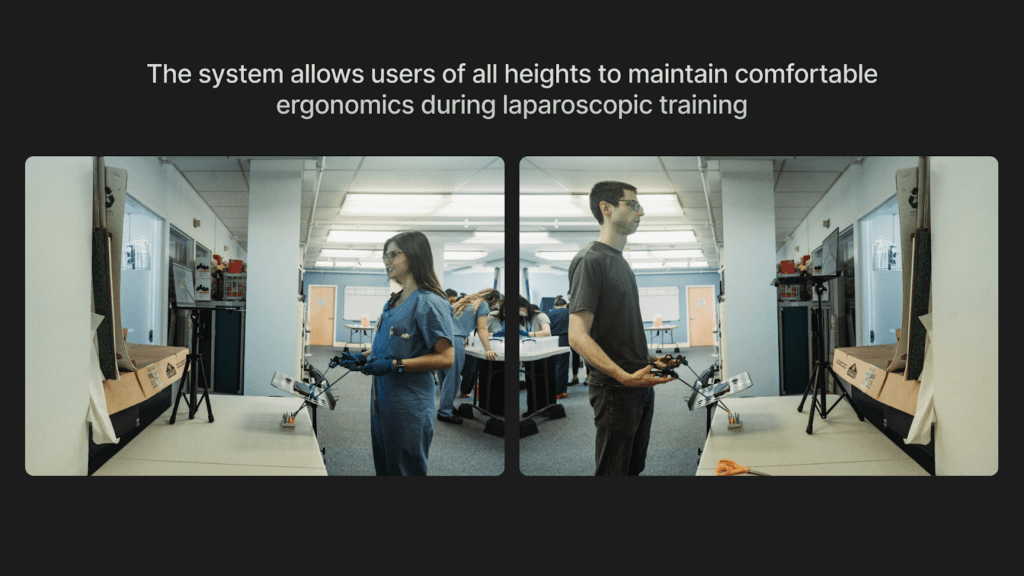

For this collaboration with the UCSF Makers Lab, they came together to try to address a common (literal) pain point for general surgery residents learning laparoscopic surgery. One of the core missions of the Surgical Innovations program is to improve surgeon ergonomics. Poor ergonomics while operating, while often overlooked, is a significant source of surgeon morbidity. Most current approaches to improve surgeon ergonomics include intra-operative interventions such as taking breaks. However, these interventions are often insufficient to prevent injury. Forcing ideal posture while learning surgery itself provides the best opportunity for long-term ergonomic improvement.

Q: What did you make?

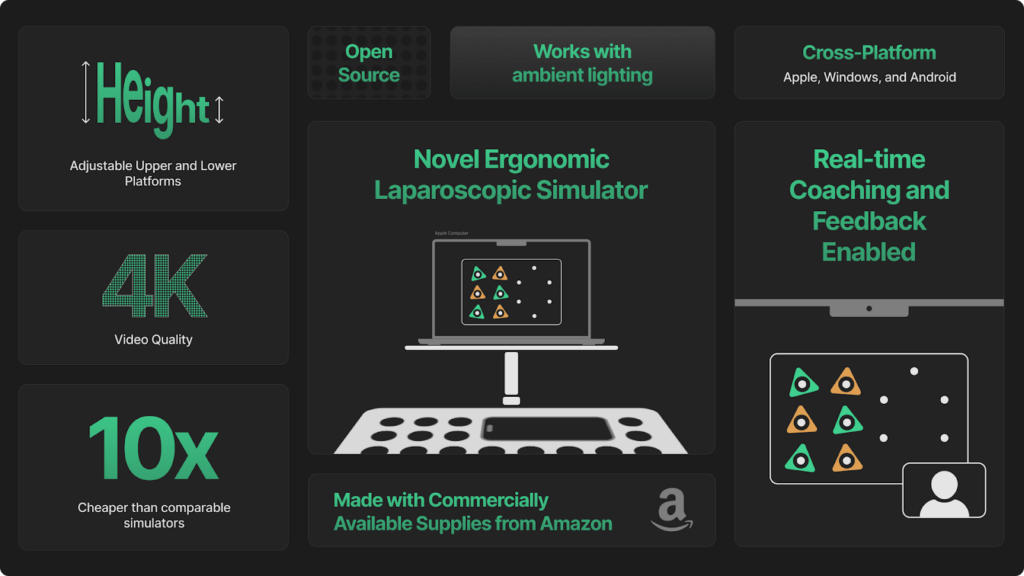

We developed a low-cost, portable home laparoscopic trainer that allows trainees of all heights to practice laparoscopic surgery in the proper ergonomic position.

Q: Why did you want to make it?

We were frustrated by the difficulty of trying to learn basic laparoscopic skills outside the operating room. The skills lab has high-fidelity, adjustable trainers, but these were not readily available outside of work hours. We were given portable trainers to take home when we were interns, but they were challenging to set up, had poor cameras, and lacked the adjustability necessary for correct ergonomics. We found they just ended up collecting dust. All these solutions were costly, ranging from several hundred to several thousands of dollars – making them inaccessible to trainees and potentially even training programs in low-resource settings. We set out to make a home laparoscopic trainer that was low-cost, portable, high-resolution allowed for real-time coaching and recording, and could replicate ideal ergonomics for all trainees.

Q: What was your process?

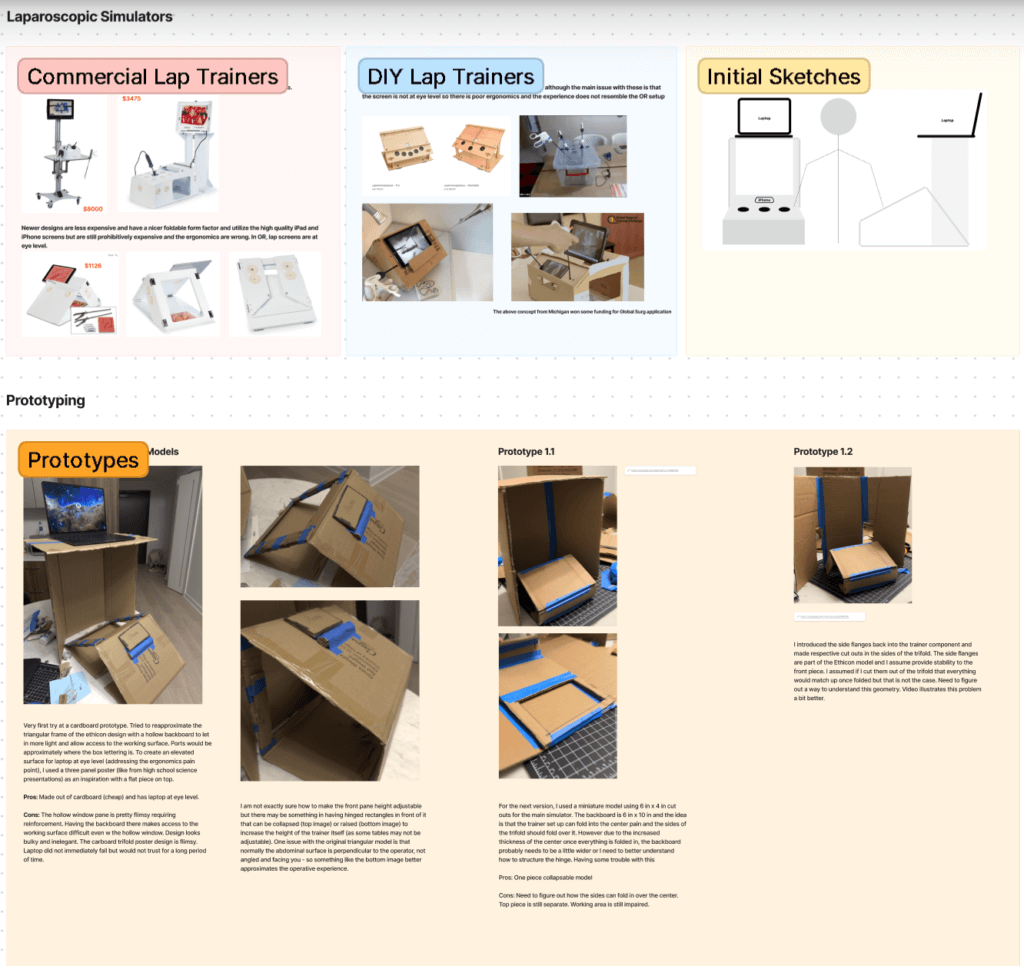

After identifying the core needs outlined above, we performed an analysis of what existing trainers did well and did poorly. We learned that we would need a readily accessible method for high-quality video, a way to independently adjust both the hand and screen height, and set our target price at less than $100. We looked at various camera systems and determined that the best solution was one that most people already have access to: a smart phone and a laptop with Zoom. For example, Apple’s Continuity Camera allows for wireless use of an iPhone camera as the webcam for a Macbook, making the iPhone the equivalent of the laparoscopic camera and the laptop the screen. This can be replicated with Android and PC systems. We looked at various height adjusting mechanisms, including ratcheting mechanisms like the one created by Makers Lab designer Scott Drapeau, telescoping stands, swing arms mechanisms, and others. We eventually settled on a pair of music stands from Amazon with telescoping adjustment and pre-cut holes fit with rubber grommets to serve as trocars. We then tested our trainer on standard tasks from the Fundamentals of Laparoscopic Surgery exam that all general surgery residents must pass.

Q: What was the hardest part of the process?

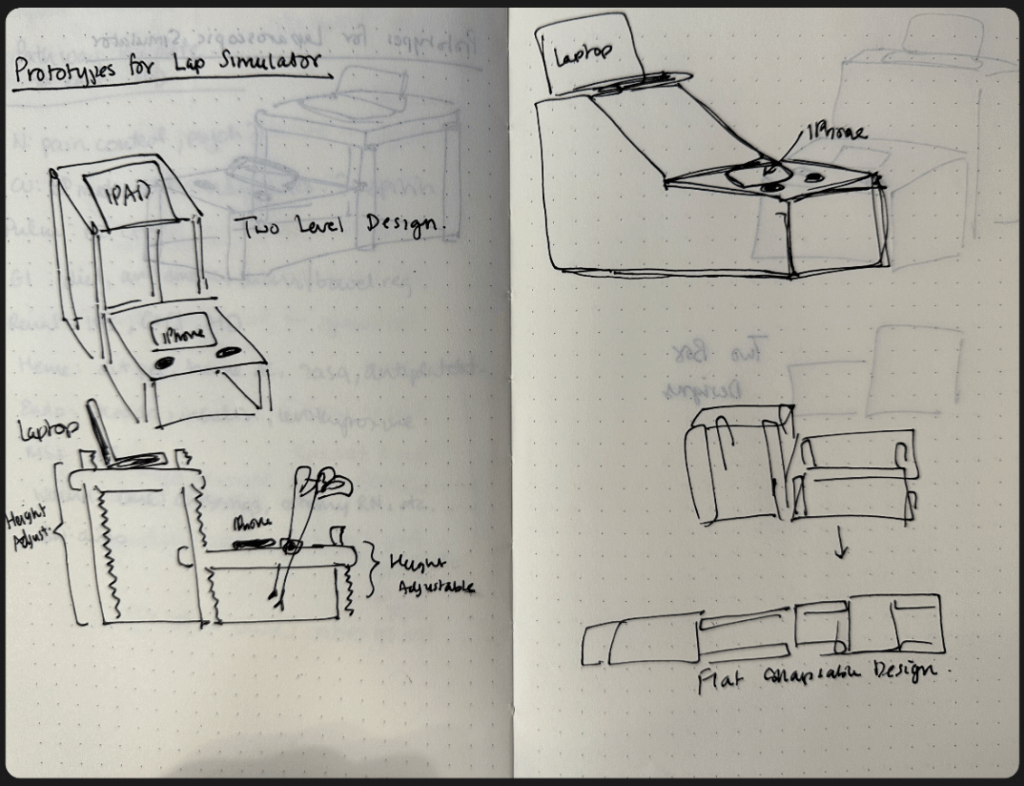

The brainstorming and initial prototyping. We generated many possible options for the camera system and height adjustment mechanism, but many were either too expensive, would require custom manufacturing, or didn’t meet other design requirements. Our initial sets of prototypes included cardboard models, creating miniature versions of designs, and full-size prototyping using representative adjustment mechanisms. In a stroke of luck, Tom stumbled upon a music stand on Amazon that met all criteria for the adjustable platform. And Tejas, ever a fan of Apple products, knew about the Continuity Camera feature. We learned that sometimes the best solutions are hiding in plain sight.

Q: What was your favorite part of the process?

Building and testing the trainer. At the UCSF Surgical Skills Center, we were able to build our trainer and compare it side-by-side to three other trainers: an expensive state-of-the-art trainer, the standard Fundamentals of Laparoscopic Surgery (FLS) trainer set, and the home trainer that we’d been frustrated with as interns. We found that our trainer had superior ergonomics to the FLS and home trainer, similar camera quality to the state-of-the-art trainer, and received overwhelmingly positive reviews from surgical residents.

Q: What do you want to make next?

One of the limitations in our existing music stand system is that there is nothing keeping the iPhone in place. To get the camera to fit over the hole exactly, we had to use tape. We also would like the final product to be more sturdy than the music stand.

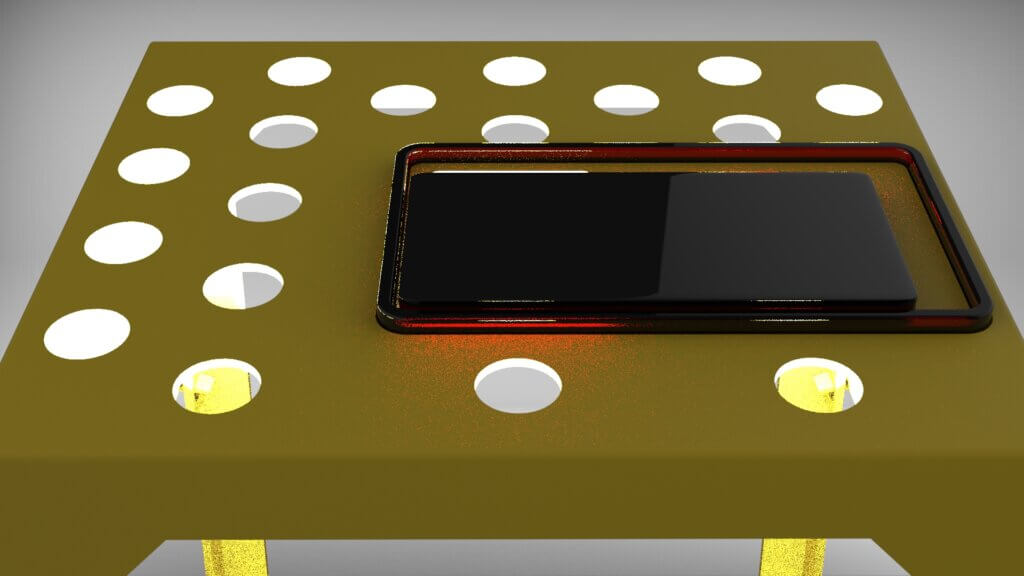

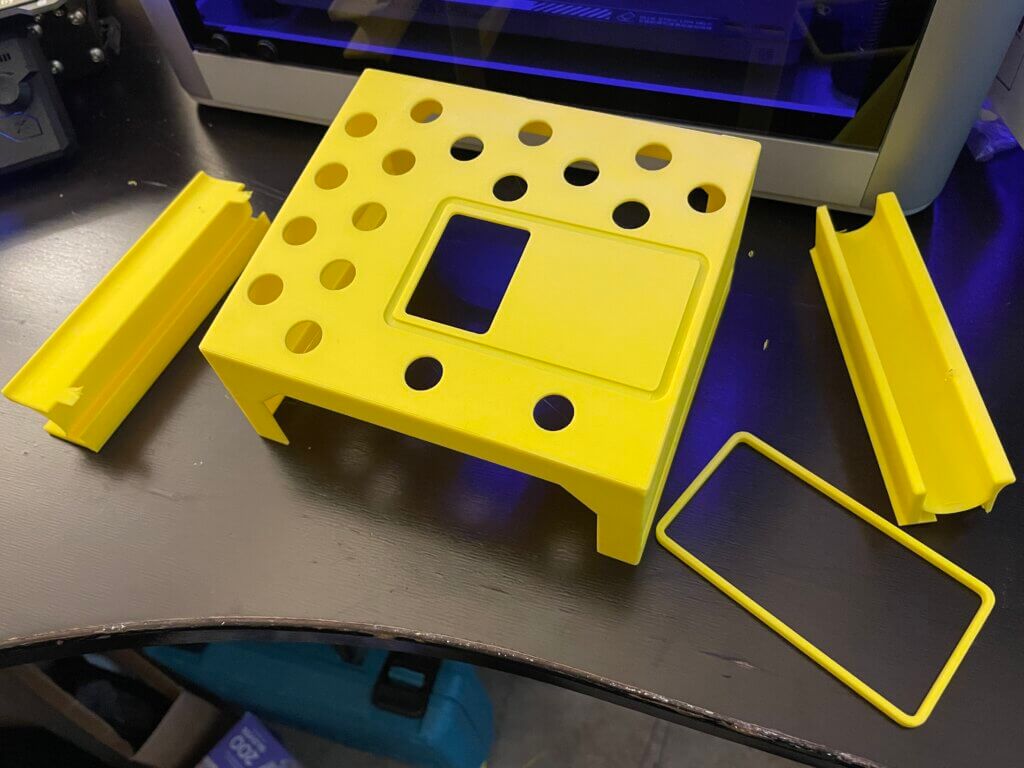

We want to develop a new bottom platform of the trainer so that it can be optimized for 3D printing in more robust material and has a built-in mount for the cell phone. We’re collaborating with the Makers Lab’s Scott Drapeau, who has designed and 3D printed the design shown below. We hope to continue to refine this concept so that surgical residents across the country have access to a low-cost, portable, ergonomic home laparoscopic trainer.

Our ultimate vision is to open-source the design file to make this product accessible to the maximum number of trainees and commercially sell a fully assembled and manufactured version.