This week’s maker is Prabhat Kumar, postdoctoral scholar in the Department of Neurological Surgery at UCSF. Let’s take a look at what Prabhat has been working on in the Makers Lab:

Q: What did you make?

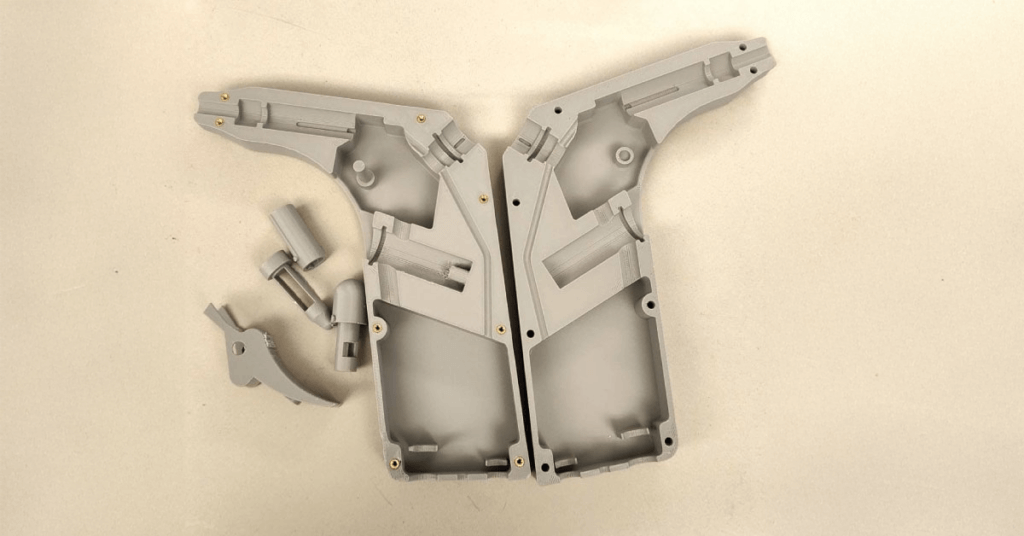

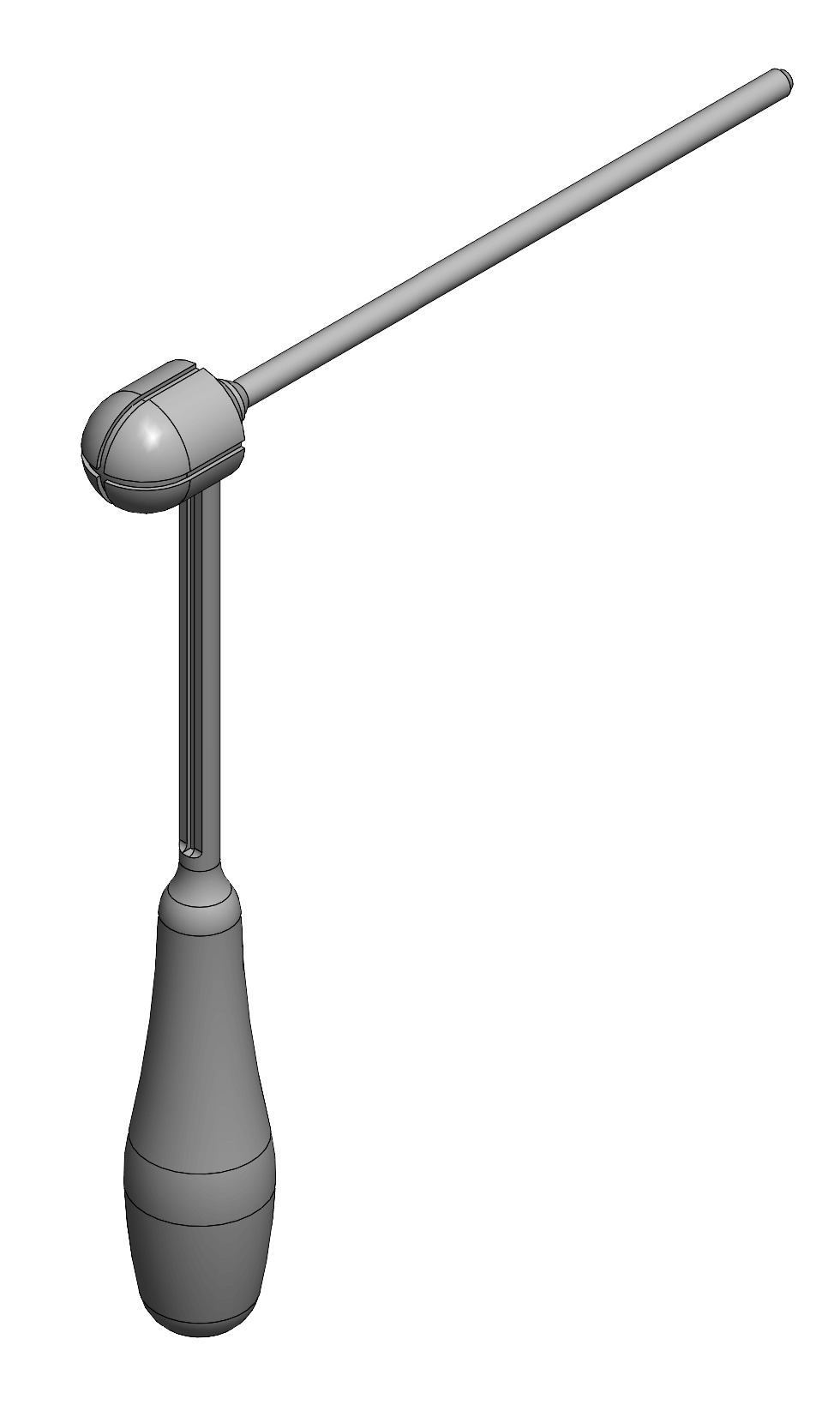

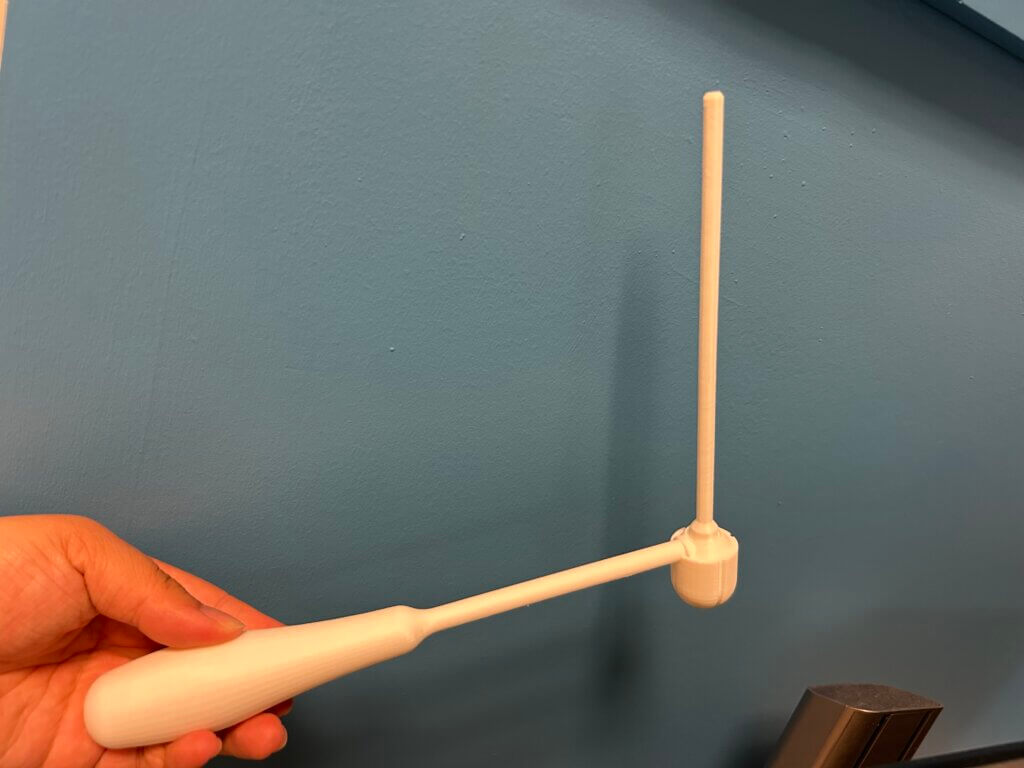

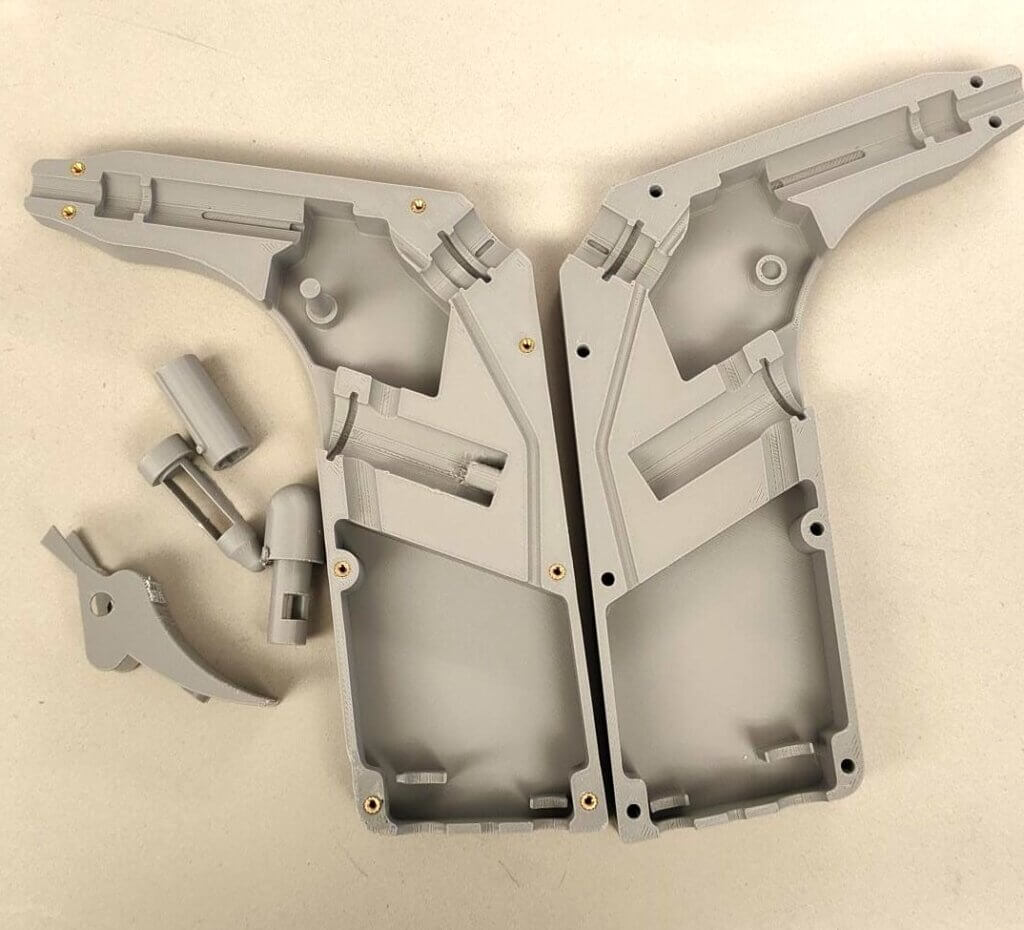

We developed a prototype for a medical device, focusing on optimizing the design, testing design concepts, and refining the mechanism for improved performance.

Q: Why did you want to make it?

The origin of this comes from the challenges faced by neurosurgeons during brain surgeries. A question arose: how can we design a device that improves precision and flexibility while maintaining control? We wanted to prototype a device that allows surgeons to perform complex procedures more effectively, addressing both technical limitations and enhancing surgical outcomes.

Q: What was your process?

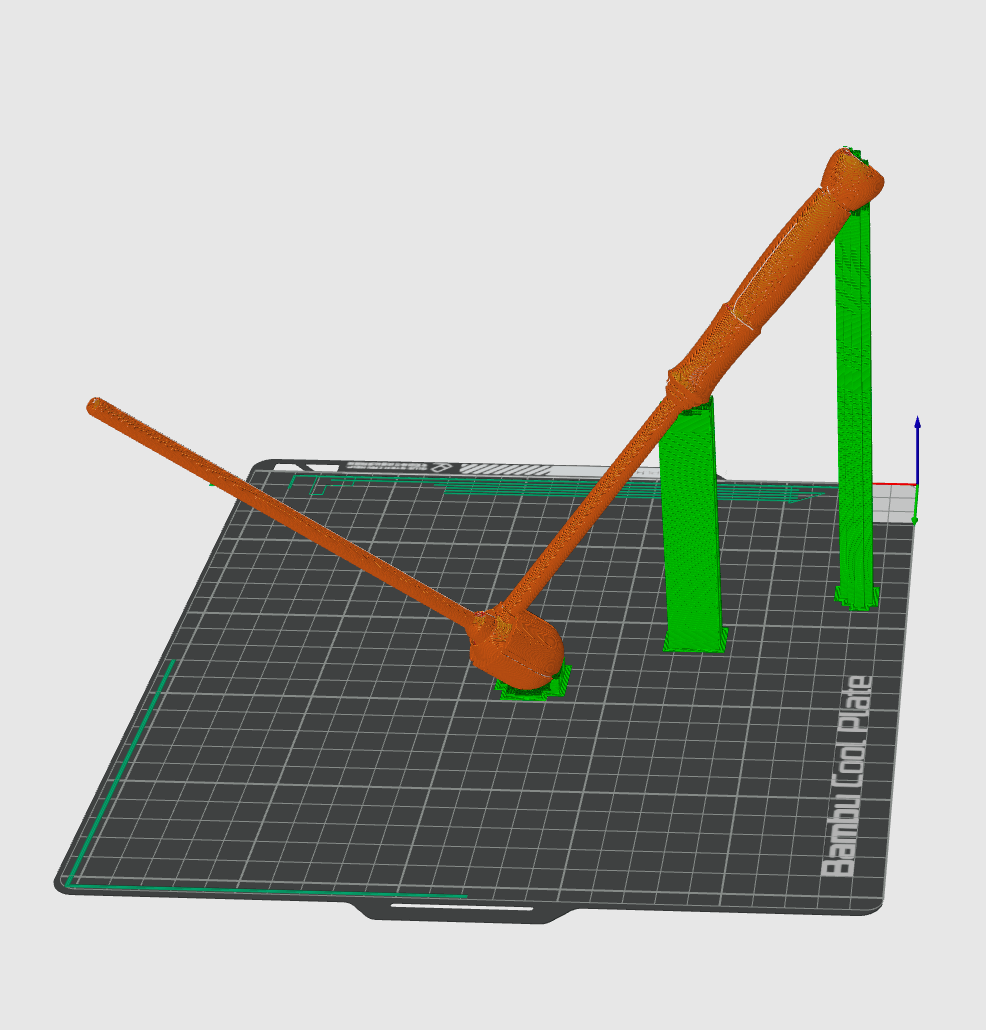

We started by identifying the key challenges in these surgeries through research and discussions with surgeons. Then, we outlined functional requirements, sketched design concepts, and performed calculations to ensure feasibility. Using CAD tools, we developed detailed designs, procured materials, and built prototypes. Each iteration underwent rigorous testing and refinements to improve performance, usability, and reliability.

Q: What was the hardest part of the process?

The hardest part was handling the prototype’s different mechanisms while balancing precision, flexibility, and structural integrity. Ensuring smooth movement in the handle prototype without compromising strength or manufacturability required multiple iterations and material adjustments.

Q: What was your favorite part of the process?

My favorite part was seeing the prototype come to life—testing the handle, making design modifications, and witnessing the improved mechanism function as intended to address real surgical challenges.

Q: How did this help make you a better postdoctoral scholar?

This process enhanced my problem-solving skills, deepened my understanding of prototyping and design iteration, and strengthened my ability to translate research into practical, impactful solutions.

Q: What do you want to make next?

Next, we would like to develop an advanced version of the device, integrating different mechanisms to enhance precision, and usability in surgical applications.