This month’s maker is Marcus H. Li, Ph.D. specialist from the Laboratory for Genomics Research with the UCSF School of Medicine. We caught up with them to see what they have been making in the Makers Lab.

Q: What did you make?

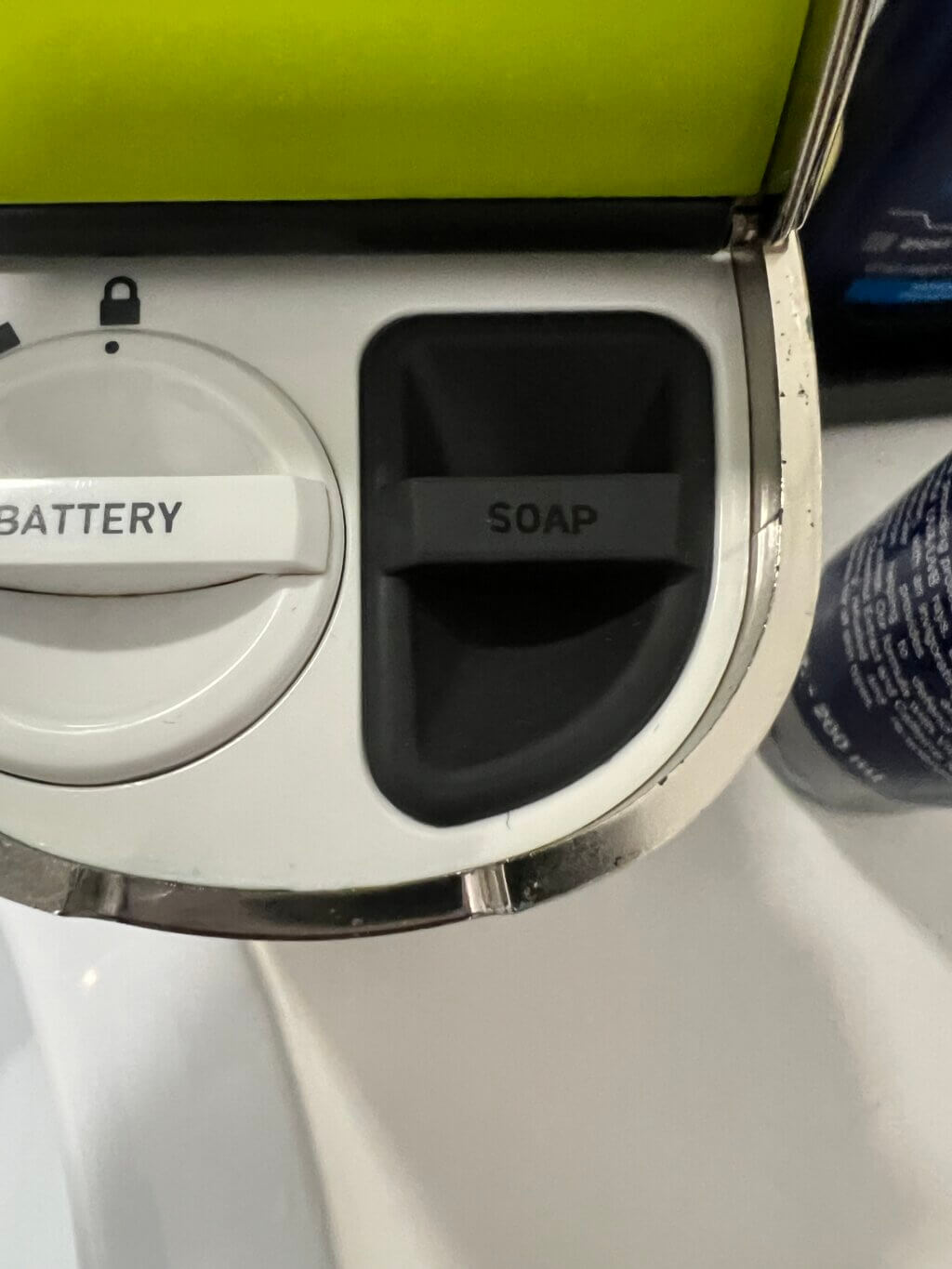

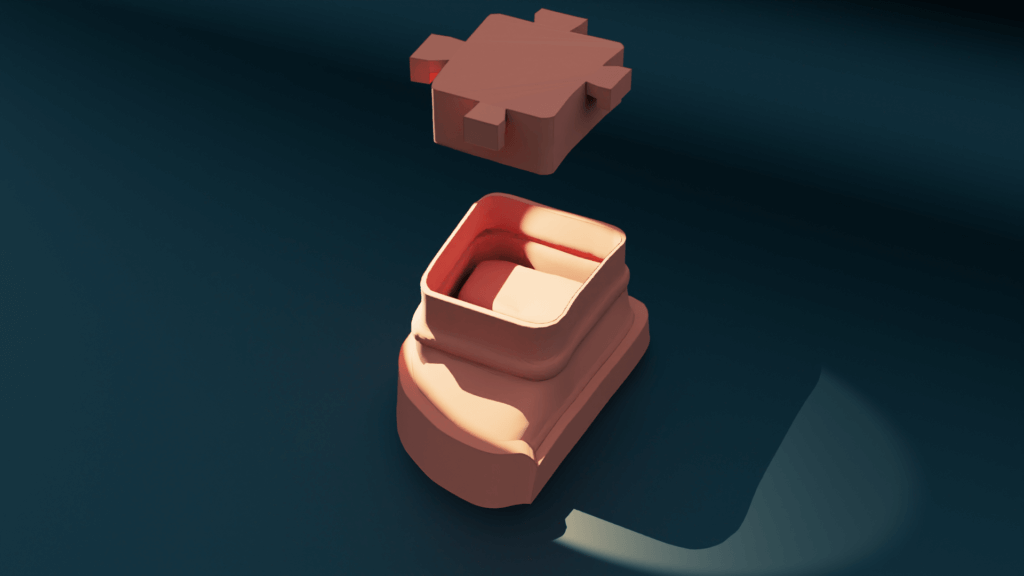

A rubber stopper for a soap dispenser in the lab.

Q: Why did you want to make it?

It is an irregular shape, and not sure if the manufacturer has a replacement for just the cap.

Q: What was your process?

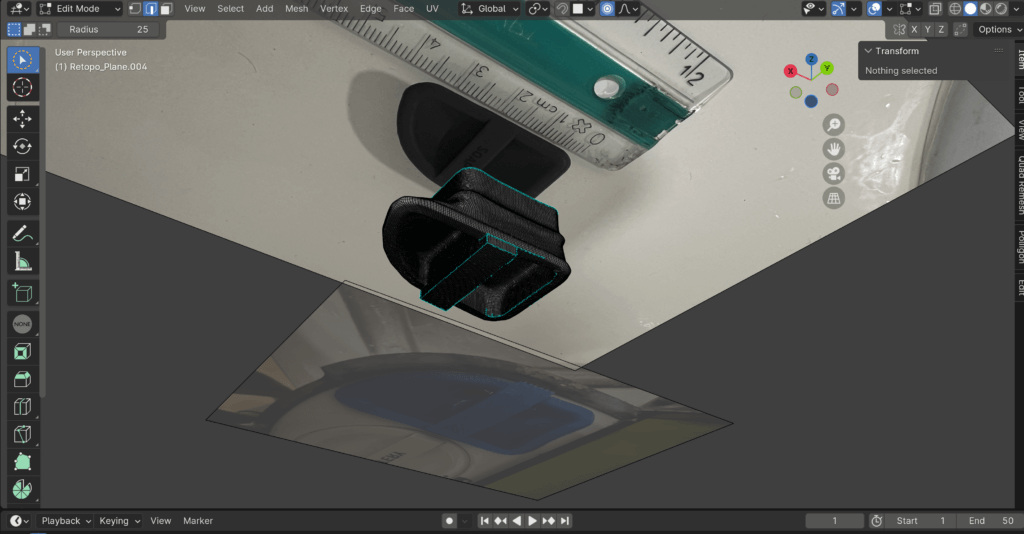

I communicated with Scott on the item, and sent the measurements along with the photos of a stopper from another dispenser. Scott wanted to 3D-scan the stopper, but didn’t because it was too small and the details would be lost, so he opted to model it in Blender with image references.

Q: What was the hardest part of the process?

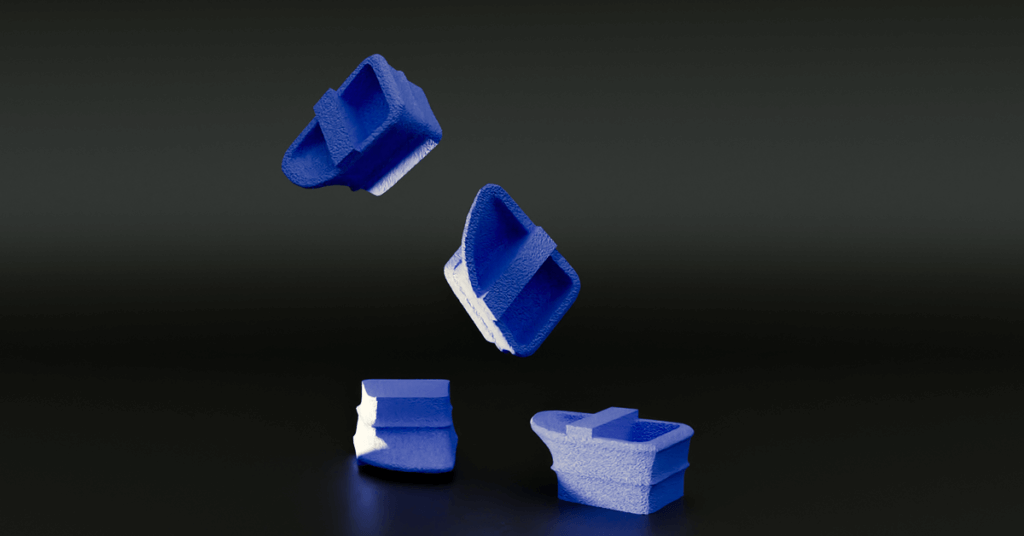

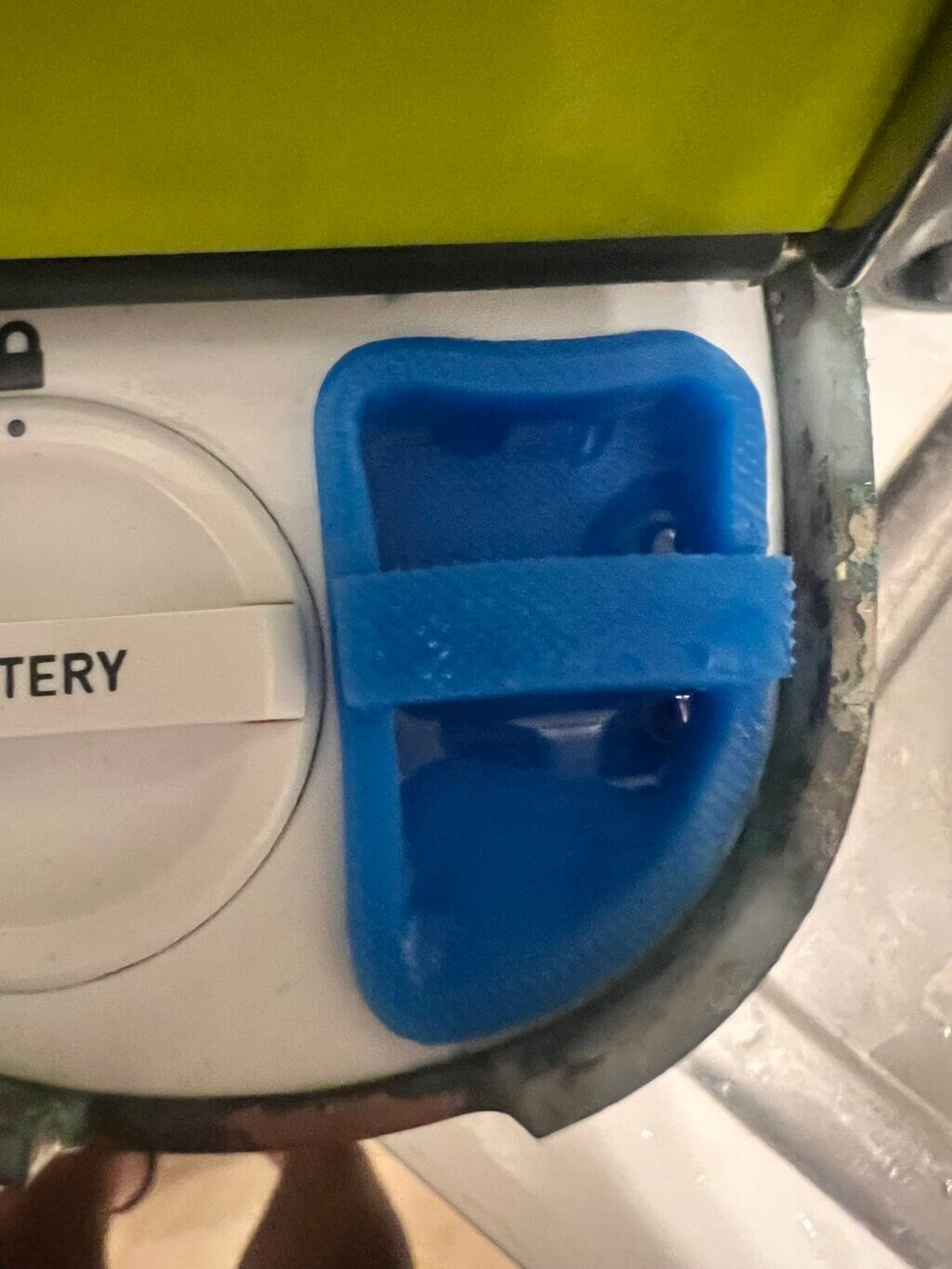

It was a fairly easy process. Originally Scott suggested printing a test of the modeled stopper in soft resin, and also did a test with flexible TPU filament, but these outputs were not up to the standards needed to replace the stopper. Scott stated “TPU is a convenient flexible filament to use in some instances, but it usually lacks detail, can be stringy, and a little too hard. Soft resin can be more ideal for softer applications, but printing in soft resin is finicky.” He decided to use silicon to cast within a 2-part 3D-printed mold, and he made some extra copies of the stopper via this process. They work nicely now.

Q: What was your favorite part of the process?

After I sent the measurements and the photos to Scott, he sent me a render of the 3D model. I was amazed how he could reconstruct the item and I appreciate his expertise.

Q: What do you want to make next

I am very impressed with the Makers Lab. Next time I may ask the Makers Lab to make some protein structures and print them out in high detail with hard resin using their Form 2.