This week’s maker is Lu Jiang, graduate student in the Department of Bioengineering at UCSF. Let’s take a look at her project.

Q: What did you make?

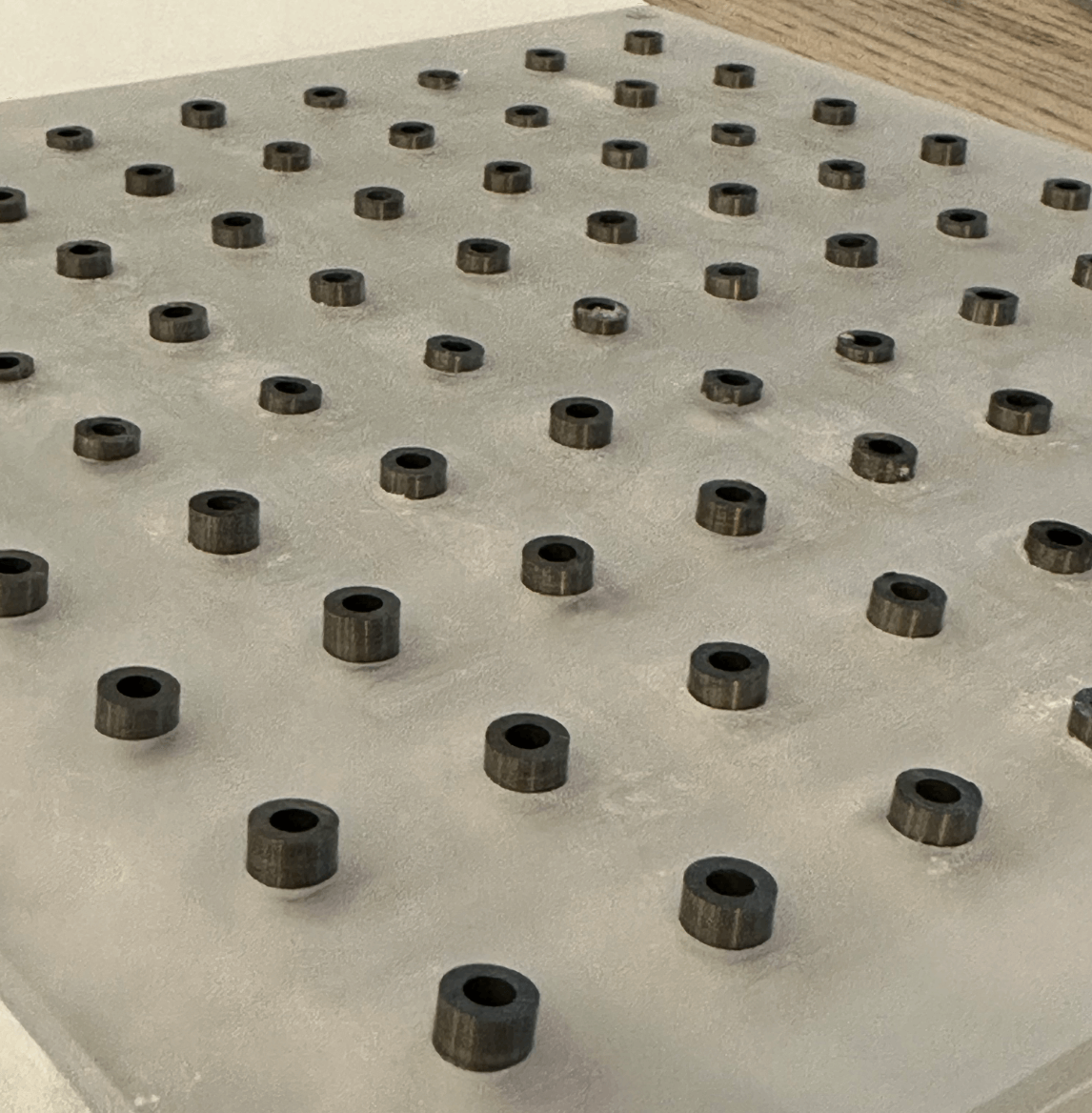

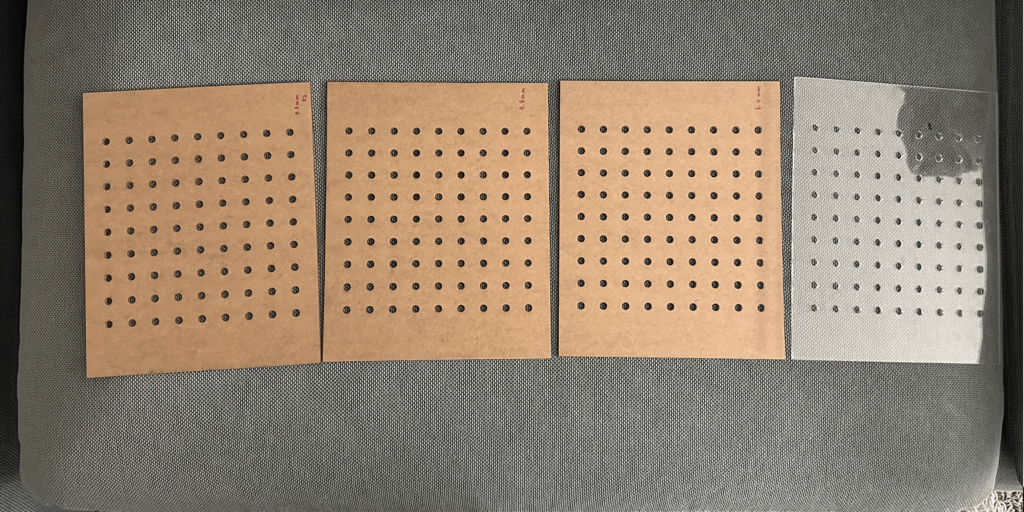

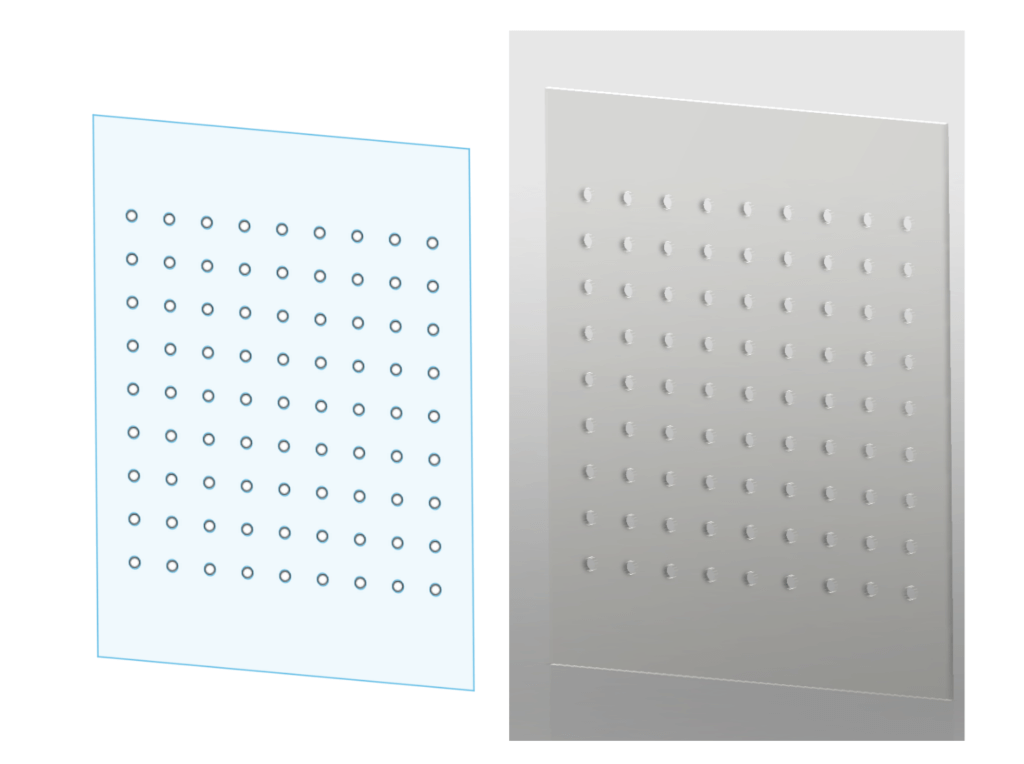

I made an acrylic sheet as an integral part of a sparse scatter sampling grid to hold alloy segments.

Q: Why did you want to make it?

It is being used for a research project in my lab. We are designing a novel sparse scatter sampling grid to study scattering in cone-beam Computed Tomography.

Q: What was your process?

I used the laser cutter at the Makers Lab to help cut holes in the acrylic sheet.

Q: What was the hardest part of the process?

The laser cutter is precise, but I needed to find the optimal hole dimensions for the alloy segments, which would not be too loose or too tight. Therefore, I cut many sheets to test which one could fit these segments best.

Q: What was your favorite part of the process?

Drawing a sketch and watching the laser cutter complete the job was the most interesting part.

Q: How did this help make you a better graduate student?

I learned how to use Autodesk Fusion 360, a powerful tool that can be useful in the future when I want to experiment with 3D printing.

Q: What do you want to make next?

I want to experiment with 3D printing other grid designs for various alloy segment arrangements and conduct X-ray experiments.