This week’s maker is Liz Guo, junior specialist in the Department of Pulmonary Medicine at UCSF. Let’s take a look at what Liz has been working on in the Makers Lab:

Q: What did you make?

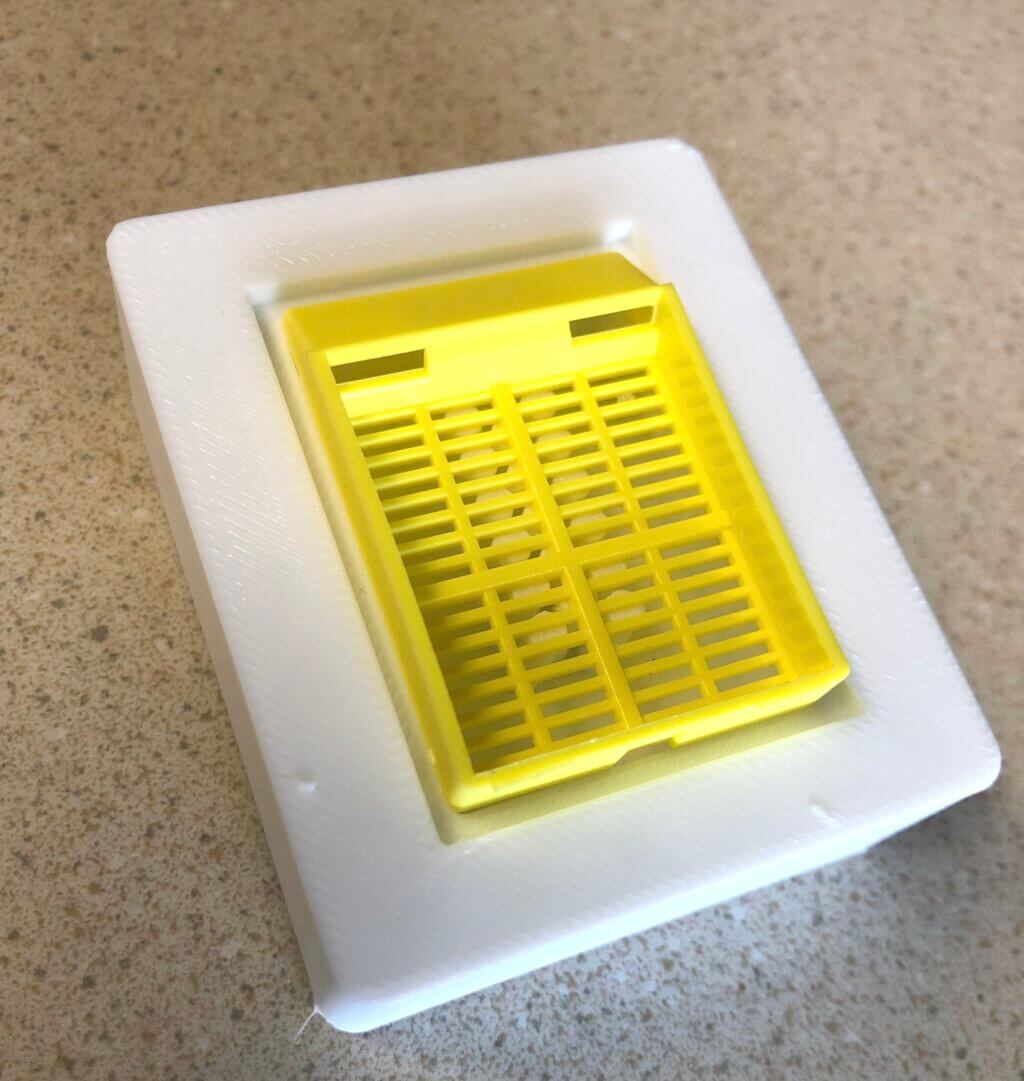

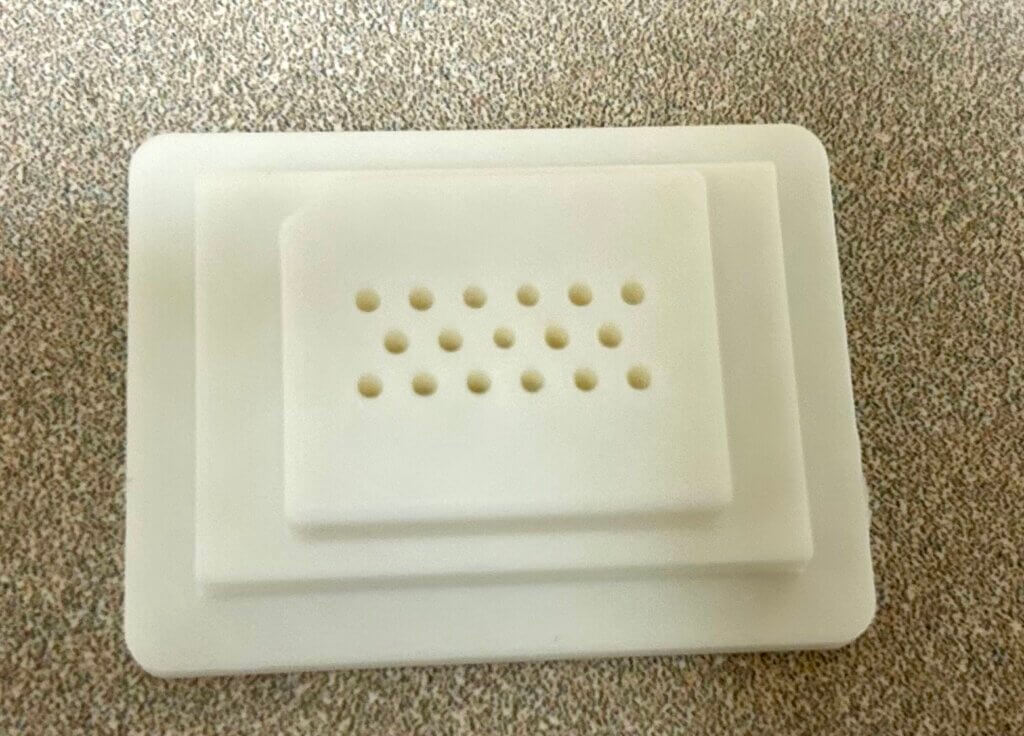

A: I made a paraffin tissue embedding mold that can produce a paraffin recipient block with 14 holes (tissue array block).

Q: Why did you want to make it?

A: We are running a spatial transcriptomic project using the Xenium platform, which is very costly. Therefore, we want to reduce costs by making tissue arrays that allow us to analyze 14 samples at a time.

Q: What was your process?

I first learned how to use the Fusion 360 CAD software and created a blueprint of the mold. After sending it to print, I tried making a paraffin block using the mold. I then modified the blueprint based on the failures, and repeated these steps until I obtained the final tissue array block.

Q: What was the hardest part of the process?

A: The hardest part is separating the paraffin block intact from the mold due to the limited material options of FDM 3D printing. I had to discuss back and forth with Jenny, the Makers Lab engineer (thank you!).

Q: What was your favorite part of the process?

A: My favorite part was to learn how to use the CAD software from scratch. I had zero experience with this, but the software is more user-friendly than I thought. It’s very exciting to create a mold according to my needs.

Q: How did this help make you a better specialist?

A: I got exposure to 3D printing and CAD software, both of which I had never used before. Now, if I have the idea, I can create my own tool!

Q: What do you want to make next?

A: Not sure yet, but I am keeping my mind open to making things that are not on the market.