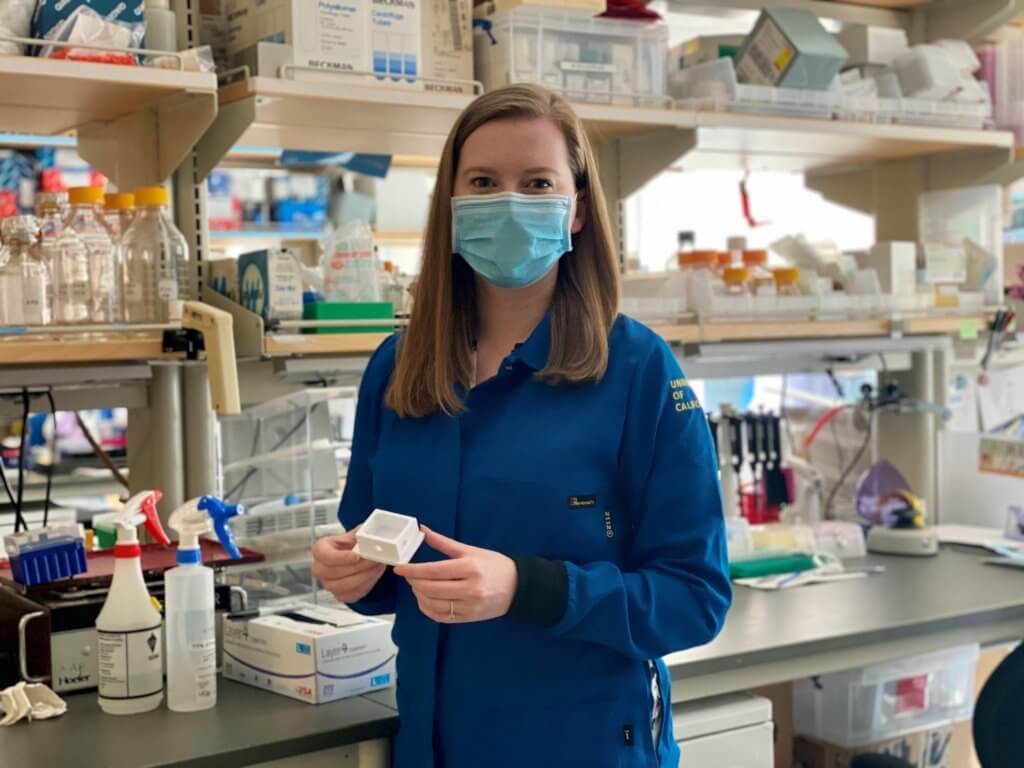

This week’s maker is Caroline Hedge, chemical program manager with UCSF Environment, Health and Safety (EHS) and UCSF Supply Chain Management. Let’s take a look at her project:

Q: What did you make?

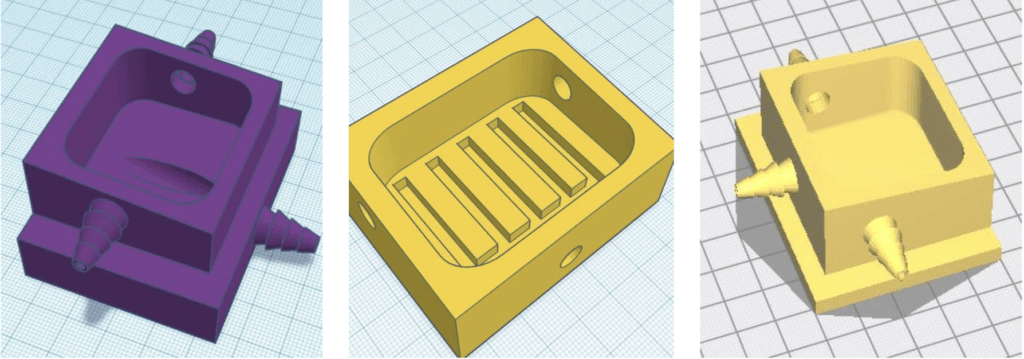

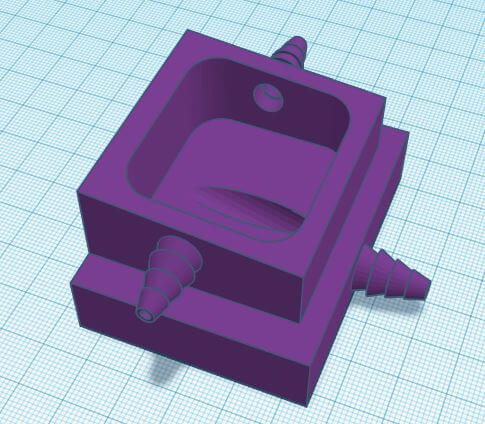

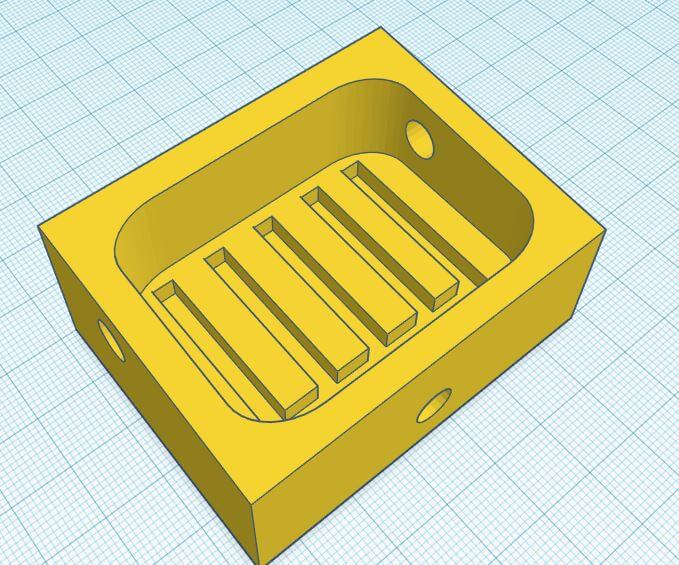

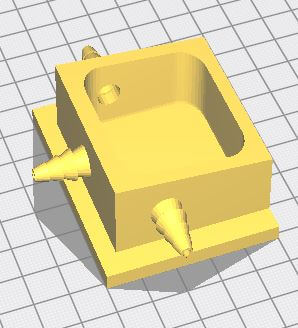

I made a waste anesthetic gas scavenger for use with stereotaxic frames during small animal surgery

Q: Why did you want to make it?

Anesthetic gases, like isoflurane, are commonly used by researchers during animal surgery, but overexposure to these gases are harmful to humans and can even cause reproductive effects or congenital abnormalities. Unlike with some chemicals, the human nose is unable to detect isoflurane until levels are far above the what is considered safe. To protect researchers from exposure to these gases, we require waste anesthetic gas scavenging systems but there are not a lot of options on the market and the products that are available can be quite costly. We developed this as a simple alternative that could be provided to researchers for free!

Q: What was your process?

I took the Makers Lab 101 class, and then 3D printing Part 1 and 2 during my lunch breaks. Word got around with my colleagues that I was learning to use the 3D printer, and our Industrial Hygiene group approached me and asked if I would be able to print a gas scavenger. I worked really closely with our local exhaust ventilation expert, Alexis, to come up with the simplest design we thought would work. From there, we made probably 6 different versions of increasing complexity and compared them against each other by visually observing the capture of smoke and measuring the face velocity, a method similar to how we test the efficiency of fume hoods.

Q: What was the hardest part of the process?

The hardest part of the process was knowing when to stop. We made so many different prototypes, some of which had in-set channels, but at the end of the day the simple version was the best version. We spent so much time trying to make it better by adding all these features that ultimately just added to the print time and didn’t improve the efficiency at all.

Q: What was your favorite part of the process?

It may sound cheesy, but the best part of this process was knowing that the effort was ultimately going to make our labs safer and healthier. UCSF’s goal is to advance health worldwide, and that starts right here on our own campus!

Q: How did this help make you a better faculty/staff member?

Working collaboratively with another group, even though they were within my department, was really fun and educational. I learned a lot about waste anesthetic gases and the different engineering factors that affect ventilation. It was a great reminder that we all have different knowledge sets and skills, and we achieve more by working together.

Q: What do you want to make next?

Maybe something fun for myself. I started playing socially distanced D&D during the shelter-in-place so maybe I’ll make my character!

To learn more about the safe use of anesthetic gases, visit the UCSF Environment, Health and Safety website. To schedule an evaluation of your anesthetic gas setup, contact industrial.hygiene@ucsf.edu.