By Thienthy Nguyen, Jenny Tai, Dylan Romero, and Dr. Alexis Dang

3D printing has been rapidly gaining traction outside of industrial use, consequently becoming more accessible for the common consumer. The production of affordable desktop printers under $1000 and the online distribution of open-source software has opened up new opportunities for hobbyists and professionals of educational institutions, allowing them the ability to explore both creative and health science applications.

A Brief History

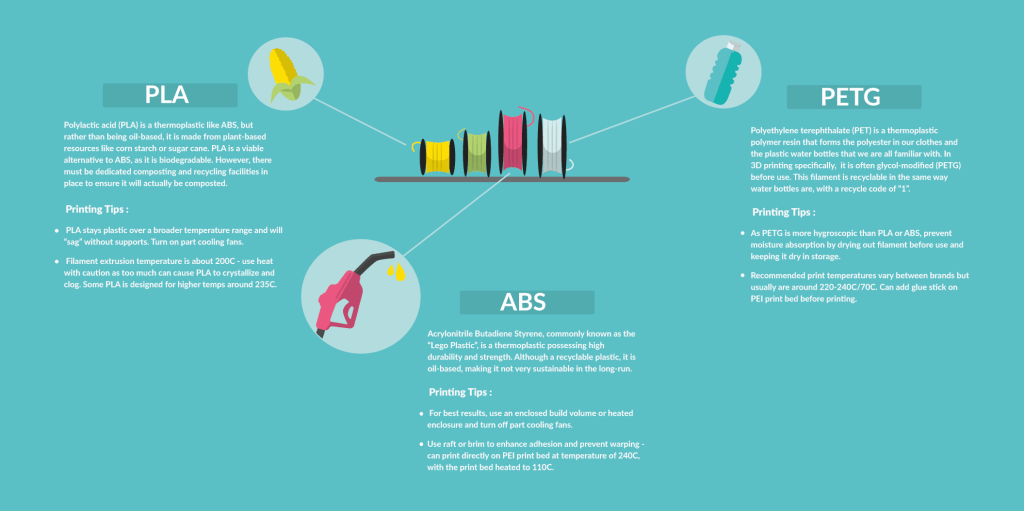

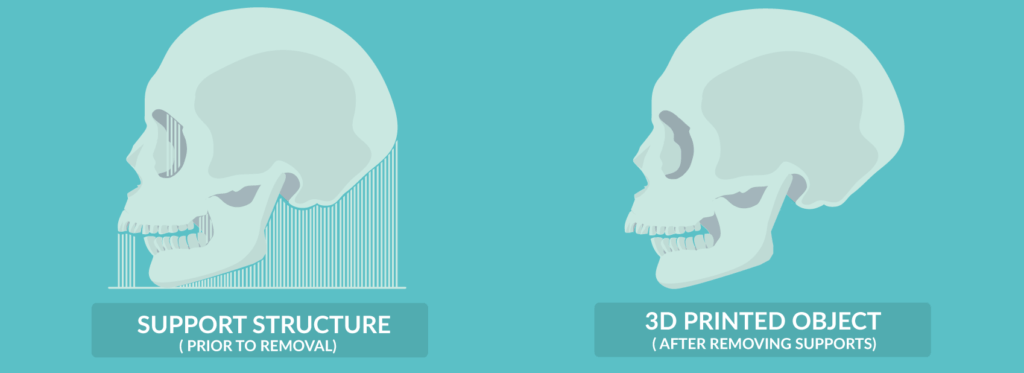

Production material is one of the most important aspects to consider when 3D printing. Many types of 3D printing materials exist on the market today, and as each material has different properties, selecting the one that is most suitable for the purposes of a 3D print is necessary to ensure the print’s desired outcome. The main production material used in 3D printing is plastic filament. The need for plastic filament came with the introduction of fused deposition model printing (FDM) when Scott Crump invented the process in 1989 and patented it in 1992 (Crump). In FDM printing, the 3D printer pushes filament through a heated extruder, melting it so it may be laid down layer by layer onto the printbed. The process repeats, with the plastic cooling and setting each time, binding each layer together to create the desired shape. Crump would eventually go on to found one of the biggest giants of the 3D printing industry, Stratasys. Stratasys became known for the two types of filament it would use to print — the model material that the object was actually made from, and the support material that held up the model as it was printing to prevent sagging. While many types of 3D printing filaments and materials exist on the market today, the model material that Stratasys chose to perfect in their machines was ABS, setting a standard for modern 3D printers.

ABS (Acrylonitrile Butadiene Styrene)

![]() The material with the longest history in the 3D printing world is Acrylonitrile Butadiene Styrene, or ABS, best known for being the colorful plastic Legos are made out of. It is a thermoplastic that is very malleable when heated so it can be changed into a certain shape. As it cools, it hardens and sets to create the solid object. ABS offers high durability and strength, while maintaining an average amount of flexibility. However, printing ABS can be challenging because it exhibits high shrinkage and warpage. These effects can be mitigated with use of an enclosure. At the moment, Stratasys holds a patent on heated enclosures, so the consumer must either build it themselves or purchase printers that have enclosures, with no specific methods to keep it at a constant temperature (Crump and Batchelder). While ABS is a recyclable plastic, it is still oil-based so it will not be sustainable in the long run. In addition, it produces the foul smell of “burning plastic” as it is being printed, requiring proper ventilation in order to negate the fumes.

The material with the longest history in the 3D printing world is Acrylonitrile Butadiene Styrene, or ABS, best known for being the colorful plastic Legos are made out of. It is a thermoplastic that is very malleable when heated so it can be changed into a certain shape. As it cools, it hardens and sets to create the solid object. ABS offers high durability and strength, while maintaining an average amount of flexibility. However, printing ABS can be challenging because it exhibits high shrinkage and warpage. These effects can be mitigated with use of an enclosure. At the moment, Stratasys holds a patent on heated enclosures, so the consumer must either build it themselves or purchase printers that have enclosures, with no specific methods to keep it at a constant temperature (Crump and Batchelder). While ABS is a recyclable plastic, it is still oil-based so it will not be sustainable in the long run. In addition, it produces the foul smell of “burning plastic” as it is being printed, requiring proper ventilation in order to negate the fumes.

ABS Printing Tips:

- Use PEI, painters tape with glue stick, or ABS slurry on glass.

- Enhance adhesion and prevent warping with the use of a raft or brim when printing.

- Filament extrusion temperature is around 240C with a heated build plate of 110C.

- Requires an enclosed build volume or heated enclosure with part cooling fans turned off.

With the level of difficulty involved with printing ABS material, the market has opened up for different types of filaments that are potentially more sustainable and eco-friendly. Competitors of Stratasys previously setting their sights exclusively on ABS printers have since experienced a change in that mindset. CEOs like Andrew Rutter of Type A Machines, a manufacturer of 3D printers that are certainly capable of printing with ABS, have chosen instead to focus on the following more sustainable options.

PLA (Polylactic Acid)

![]() Polylactic acid (PLA) is a thermoplastic like ABS, but rather than being oil-based, it is made from plant-based resources like corn starch or sugar cane. As a thermoplastic, it is similar in strength as ABS, but does not require as intense of a heating temperature. It has very little flexibility, and can be more brittle. There are now multiple variations of PLA and PLA composites that can improve PLA’s heat resistance, impact resistance, and durability. In contrast to ABS, it does not smell as much while printing (some even say the smell is pleasant), and has minimal shrinkage and warping as it cools. PLA’s biggest strength is that it is biodegradable, so it is a sustainable and eco-friendly material. While PLA is a very viable alternative to ABS, there must be dedicated composting and recycling facilities towards it so it will actually be composted. In the interests of creating health science models, PLA is recommended for its ease of printing, low cost, and potential for bio-compostability.

Polylactic acid (PLA) is a thermoplastic like ABS, but rather than being oil-based, it is made from plant-based resources like corn starch or sugar cane. As a thermoplastic, it is similar in strength as ABS, but does not require as intense of a heating temperature. It has very little flexibility, and can be more brittle. There are now multiple variations of PLA and PLA composites that can improve PLA’s heat resistance, impact resistance, and durability. In contrast to ABS, it does not smell as much while printing (some even say the smell is pleasant), and has minimal shrinkage and warping as it cools. PLA’s biggest strength is that it is biodegradable, so it is a sustainable and eco-friendly material. While PLA is a very viable alternative to ABS, there must be dedicated composting and recycling facilities towards it so it will actually be composted. In the interests of creating health science models, PLA is recommended for its ease of printing, low cost, and potential for bio-compostability.

PLA Printing Tips:

- Turn on part cooling fans — PLA stays plastic over a broader temperature range and will “sag” without supports.

- Optimal filament extrusion temperature is around 200C – heat should be used with caution as it can cause PLA to crystallize and clog.

- A heated build plate is not required, but if available will need to be heated to 60C.

PETG (Polyethylene Terephthalate Glycol-Modified)

![]() Another plastic filament that is quite familiar to consumers is polyethylene terephthalate (PET), which is a thermoplastic polymer resin that forms the polyester in our clothes, as well as the plastic water bottles that we are all familiar with. In 3D printing specifically, the plastic is often glycol modified (PETG) and regular PET is seldom used. It has high strength and durability while maintaining a good amount of flexibility. It has very good layer adhesion so 3D prints come out strong, but requires a bit more fine tuning with the print settings than materials like PLA. Objects made from PETG get surface scratches more easily than ABS, and the filament is hygroscopic, so it easily absorbs moisture from the air. This would cause the filament to bubble and pop while printing, so the filament would need to be sealed, and kept in a cool and dry place. The filament is also recyclable, the same way our water bottles are, with a recycling code of “1”.

Another plastic filament that is quite familiar to consumers is polyethylene terephthalate (PET), which is a thermoplastic polymer resin that forms the polyester in our clothes, as well as the plastic water bottles that we are all familiar with. In 3D printing specifically, the plastic is often glycol modified (PETG) and regular PET is seldom used. It has high strength and durability while maintaining a good amount of flexibility. It has very good layer adhesion so 3D prints come out strong, but requires a bit more fine tuning with the print settings than materials like PLA. Objects made from PETG get surface scratches more easily than ABS, and the filament is hygroscopic, so it easily absorbs moisture from the air. This would cause the filament to bubble and pop while printing, so the filament would need to be sealed, and kept in a cool and dry place. The filament is also recyclable, the same way our water bottles are, with a recycling code of “1”.

PETG Printing Tips:

- Apply glue stick onto painters tape, PEI sheet, or directly onto glass before printing.

- Recommended filament extrusion temperature is 240-260C, with a heated build plate of 60C.

- As a hygroscopic material, PETG will need to be kept dry or dried before use.

Nylon

Nylon (polyamide) filament is often found in its synthetic polymer form, but there are variants of Nylon that are biopolymers. It has very high strength and durability, while maintaining a high amount of flexibility in its structure. Nylon filament can also be dyed to create unique color combinations in user creations. Certain types of nylon are also biocompatible so prints may be useful in the clinical field. However, nylon is very hygroscopic and it undergoes considerable shrinkage and warping while cooling. While nylon is recyclable, many recycling facilities may not be equipped to handle nylon so any prints and waste found in the facility could be transferred straight to landfills. With multiple variations of nylon (Nylon 11,12, etc.) the source of the nylon may or may not be sustainable and recyclable, and these nylon variants will also have different material properties.

Nylon Printing Tips:

- Requires an all-metal hotend as extrusion temperatures are 240-260C.

- Heated build plate needed, with a temperature of 110C.

- Will need to be actively dried prior to printing as it is very hygroscopic.

- Apply glue stick directly onto glass printbed for best results.

Other Filament

Other 3D printing materials include thermoplastic elastomers (TPE) and its variants of polyurethane (TPU) and copolyesters (TPC), plastics with rubber-like qualities. These materials can be quite elastic unlike the other filaments, providing increased flexibility in addition to being tear-resistant and soft. Among these is polycarbonate, one of the strongest materials that can be used in 3D prints. Its transparency and excellent light transmittance can make it an attractive option, and the requisite to print at high temperatures up to 300C allows it to undergo minimal shrinkage or warping. Although attractive options, these materials are not always recommended for use as they fall under the recycling code of “7”, a category of plastics that cannot be recycled.

An overview of some of the above filaments can be viewed in the image below (click to zoom):

This is not a complete listing of all the possible materials that can be printed with an FDM printer, but serves as a guide to help users understand and evaluate the characteristics of commonly used 3D printing materials.

But what does it mean to be sustainable? To be biodegradable? These terms pop up in material descriptions and business mottos all the time, but rarely do they outline and define what that means to the company and the consumers. The EPA defines sustainability to be “…based on a simple principle: Everything that we need for our survival and well-being depends, either directly or indirectly, on our natural environment. To pursue sustainability is to create and maintain the conditions under which humans and nature can exist in productive harmony to support present and future generations.” In essence, sustainability for producers and consumers of 3D printing filament would mean pursuing the use of plastics that are able to be reused and remade into other products, rather than continuing to work with non-recyclable materials that will only end up in our oceans and landfills.

At the moment, plastic has become an even bigger waste problem than before. 9.1 billion tons of plastic have been produced in total, and only about 30% of it is still in use today (Greene). Of the 6.9 billion tons of waste, 9% has been recycled and 12% has been incinerated. 79% of it is sitting in landfills, randomly thrown about on land, or gathering in gyres in the seas. A large and slow moving currents system that helps move ocean waters around the globe is consequently gathering all our plastic waste into patches around the ocean. Currently, there are two massive patches of floating debris in the Pacific Ocean: one located in the North Pacific, and a recently discovered one located in the South Pacific. The animals that live in these gyres are now consuming microbeads and strips of plastic that suck up chemical pollutants, and these animals eventually travel up the food chain by being consumed by fish, and in the end — humans. These chemical pollutants have been linked to cancer and hormone disruption.

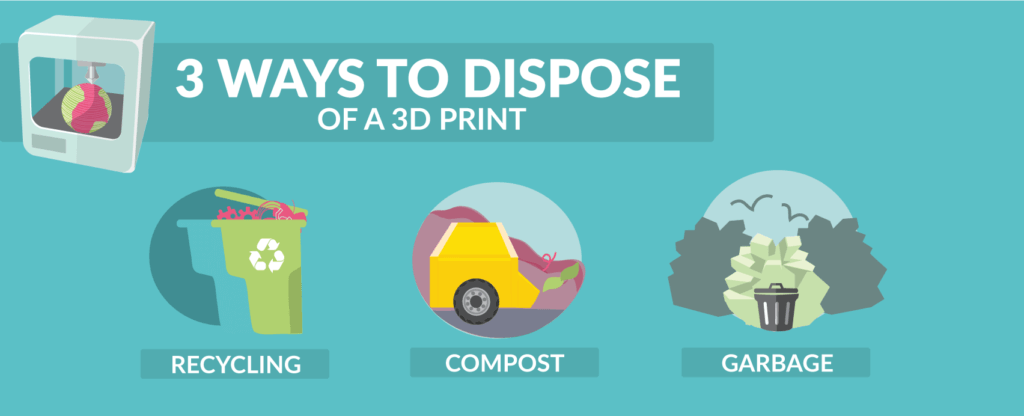

When talking about plastics, degradability, biodegradability, and compostability are three terms often used. A common misconception is that if a plastic is degradable, then that means it is an “eco-friendly” material that does not contribute to our building plastic waste. Degradation simply means that the object is able to be broken down into tiny pieces. All plastic is degradable, and some additives can even be added to make the plastics become either brittle enough to crumble in sunlight or able to break down by oxidation. However, at the end of the day the plastics will not disappear, just remain as really small pieces. The long chains of polymers that plastic is comprised of will still exist and will not be able to be used by the organisms that consume them, and may even cause build up in these organisms that attract toxic residues, propagating harmful effects on the environment.

Plastics that are biodegradable, on the other hand, can be broken down by microorganisms. They can be digested so that the carbon atoms in the polymer chains are broken apart and used by the organisms themselves, returning the plastics to the carbon cycle of the Earth. In addition, if a plastic is compostable, it will biodegrade in a certain amount of time under the right conditions. All bioplastics eventually degrade, but if sealed in an airtight room, the process could take thousands of years. Compostable plastics often break down into carbon dioxide, water, and biomass, and also support plant growth. The only catch is that the plastics have to be put through the right conditions. Therefore, it is not recommended to throw 3D printed creations into a home composting bin. PLA, for example, needs to be composted in a facility at high temperatures with a good amount of oxygen and organic substrate for about 3 months. Many composting facilities, however, are sifted through every 60 days and any plastic found may be thrown into the trash (and subsequently straight to the landfill), disrupting the compostability of PLA.

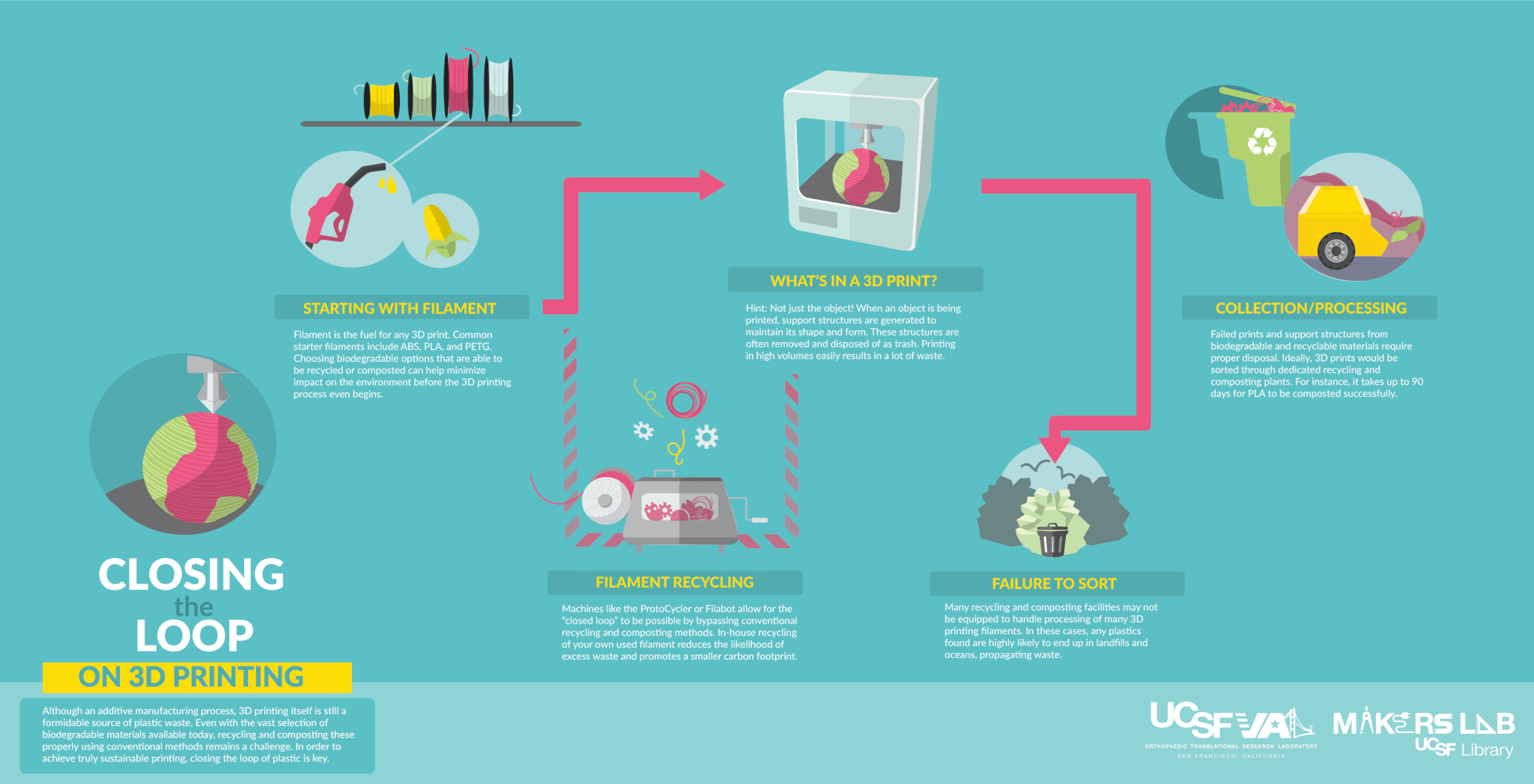

Although 3D printing is known to be less wasteful for production since it specializes in “additive” manufacturing — processes which use only the exact amount of plastic source material as needed— it still generates a good amount of waste. When an object is being printed, support structures are generated to maintain its shape and form. However, these support structures are often cleaned up and removed, then disposed of as trash. The ideal 3D printed object would not require any support, but that can prove to be a troublesome task when trying to create more complicated 3D models. For the 3D design workflow in product and engineering fields it may even require 3D printing multiple iterations of a single object before achieving an intended design or functionality. In the application of printing anatomical models for use in medical education and prototyping, 3D printing makes it feasible to produce disposable models. Taking the field of orthopedics for example, 3D prints of bones created from CT scans unique to every patient are useful in surgical planning, but have a slim chance of being reused. While reducing usage of plastic as a whole would certainly be the ideal solution; there are a variety of exciting new options being developed now with this goal in mind.

Currently, a few startup companies have developed machinery and services to recycle filament. Filabot has developed an extruding machine that creates filament by grinding up plastic pellets. This way, users can control how much filament they actually use instead of having to purchase material by the kilogram. For users that want to recycle their prints but do not want to invest in a full machine setup, Filabot has also started beta-testing a recycling service where customers can send in their failed PLA prints to be recycled and turned into filament. Another option is the versatile ProtoCycler created by the startup ReDeTec, which uses the capabilities of a built-in grinder to take waste from any plastic and melt it back into usable filament spools extrudable on many 3D printers.

There are also companies attempting to combat waste by exploring unique alternatives to plastic filament. 3DomFuel, a conglomerate between the original 3D-Fuel and 3Dom, has developed Buzzed, a beer-based filament using waste from the beer brewing process. It creates a rich golden color with a grainy texture. Wound Up is a coffee-based filament created with recycled coffee grains that prints in a rich brown color and natural grain finish. More recently, Landfillament utilizes a process called pyrolysis to create printable carbon-rich char from organic materials extracted from none other than our own garbage. Timberfill, created by Czech Republic company Fillamentum, is a biodegradable filament made from recycled spruce trees. Many more PLA-based composites utilizing starch-based, hemp-based, and glass-based sources are also becoming increasingly available.

Future consumers of 3D printing must close the loop of plastic rather than letting it continue to fill our landfills and oceans. As desktop 3D printers and materials get cheaper and cheaper, it is more important than ever to start taking into account their impact on the environment. Taking the steps towards practicing sustainable 3D printing by selecting biodegradable or compostable materials and supporting solutions for recycling used plastic filaments can help increase success when 3D printing, while leaving a much smaller carbon footprint.

A visual summary of the 3D printing loop is shown in the infographic below. Click and zoom to view the image at full size:

This post has been brought to you by the UCSF Orthopaedic Surgery Department and the UCSF Library Makers Lab.

Works Cited:

Crump, Steven Scott. Apparatus and method for creating three-Dimensional objects. 9 June 1992.

Crump, Steven Scott, and John Samuel Batchelder. Method for rapid prototyping of solid models. 2 Feb. 1999.

Greene, Sean. “Plastic trash could top 13 billion tons by 2050. And recycling doesn’t help much.” Los Angeles Times, 21 July 2017, www.latimes.com/science/sciencenow/la-sci-sn-plastic-trash-20170721-htmlstory.html.