This week’s makers are Brian Haas, MD, associate professor of Radiology, Lohith Kini MD, PhD, resident in Radiology, Peter Hadar MD, epilepsy fellow at MGH, and Trevor Amarante, engineer and UC Berkeley alumnus. Let’s take a look at what they made.

Q: What did you make?

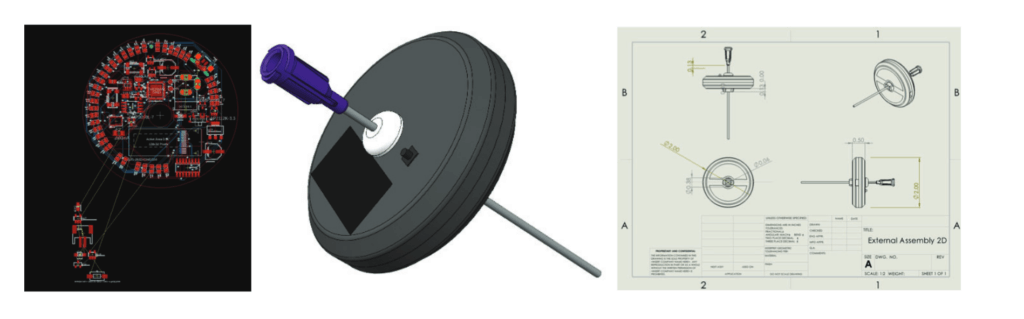

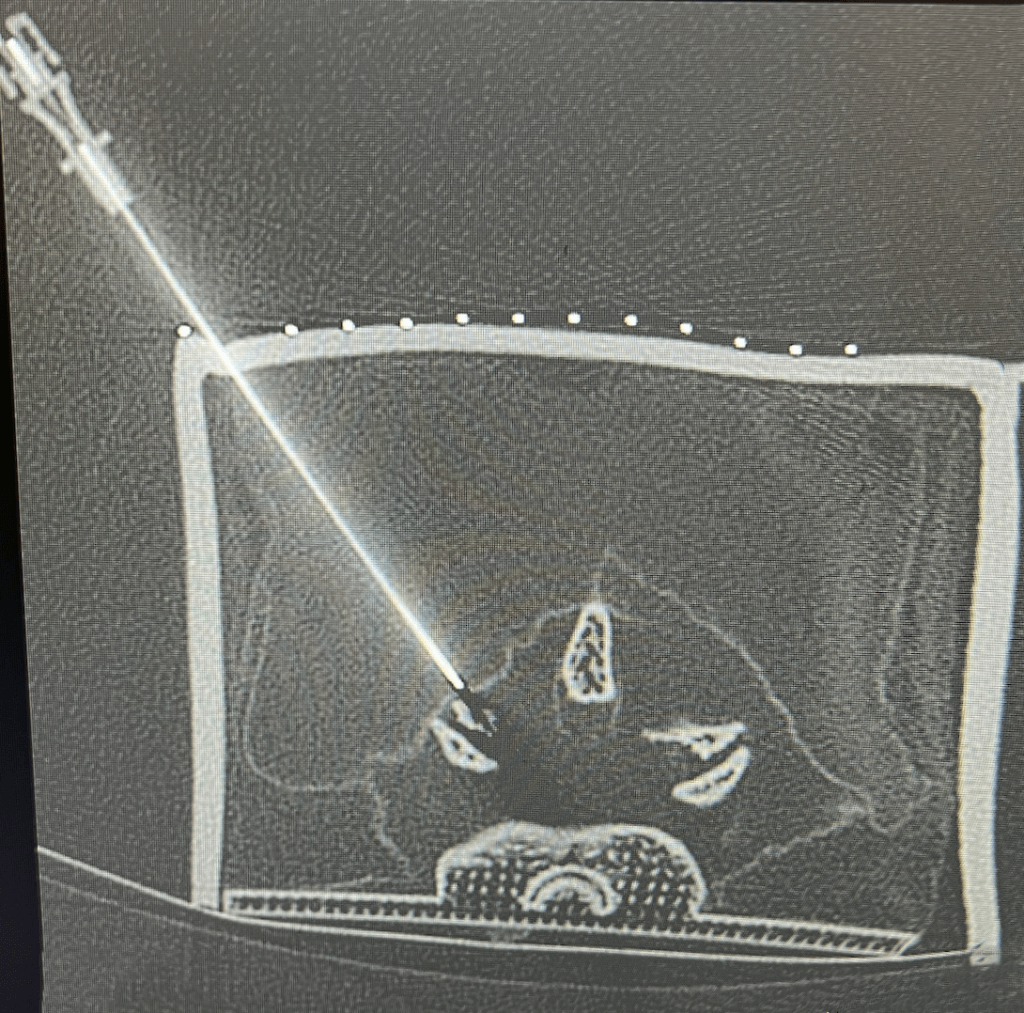

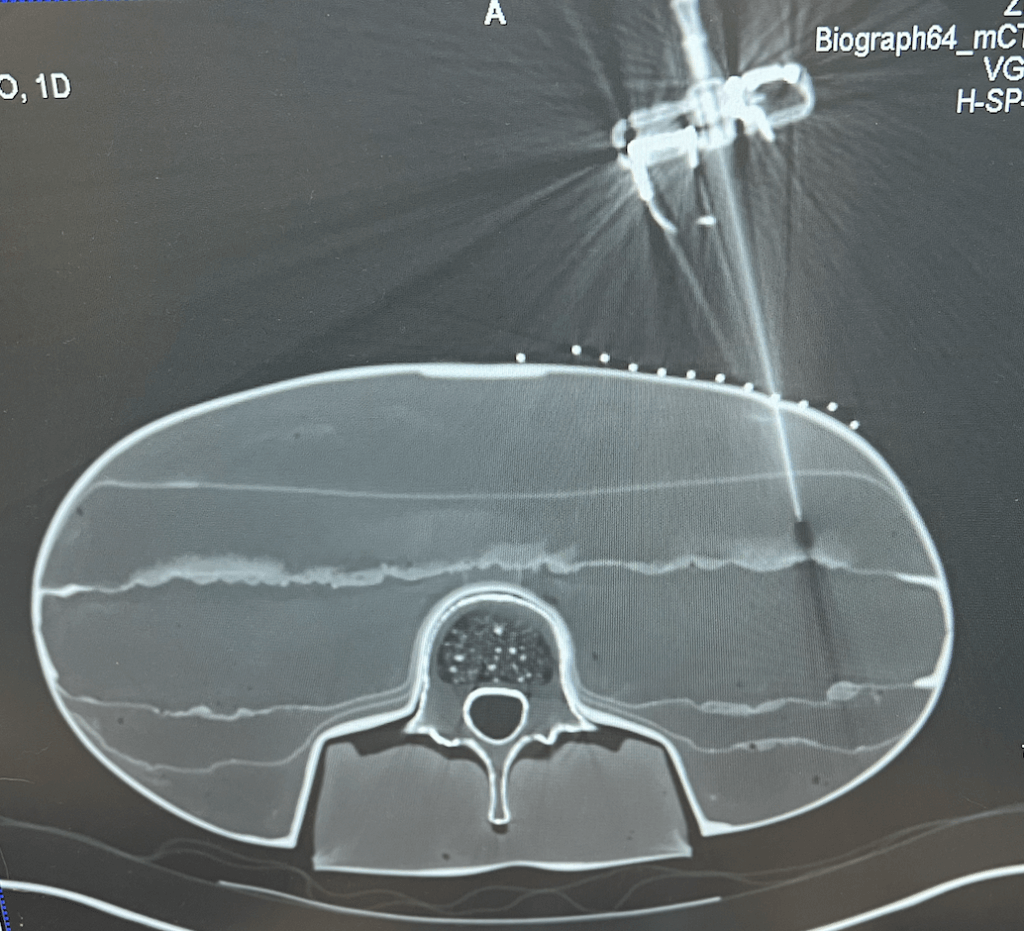

We are building NeedleGPS, which is a medical device that attaches to a needle, in order to assist with CT-guided procedures, such as biopsies for cancer diagnoses.

Q: Why did you want to make it?

We started with a desire to improve the lives of patients who undergo interventional radiology procedures, which helps inform the treatments provided. We saw that CT-guided procedures can be difficult at times, even unsuccessful, and can lead to medical complications. We expect that NeedleGPS will make CT-guided procedures faster, more accurate, and safer for patients.

Q: What was your process?

We started with a problem: why are CT-guided lung biopsies unsuccessful in 20% of cases? And what can we do to make them better? As we brainstormed ideas, we realized that a key challenge is around successfully directing the needle to the target. Getting the angle of the needle right is paramount. The current standard of care is for the radiologist to look at the images and estimate with their visual spatial skills the correct angle. We decided there had to be a better way.

Q: What was the hardest part of the process?

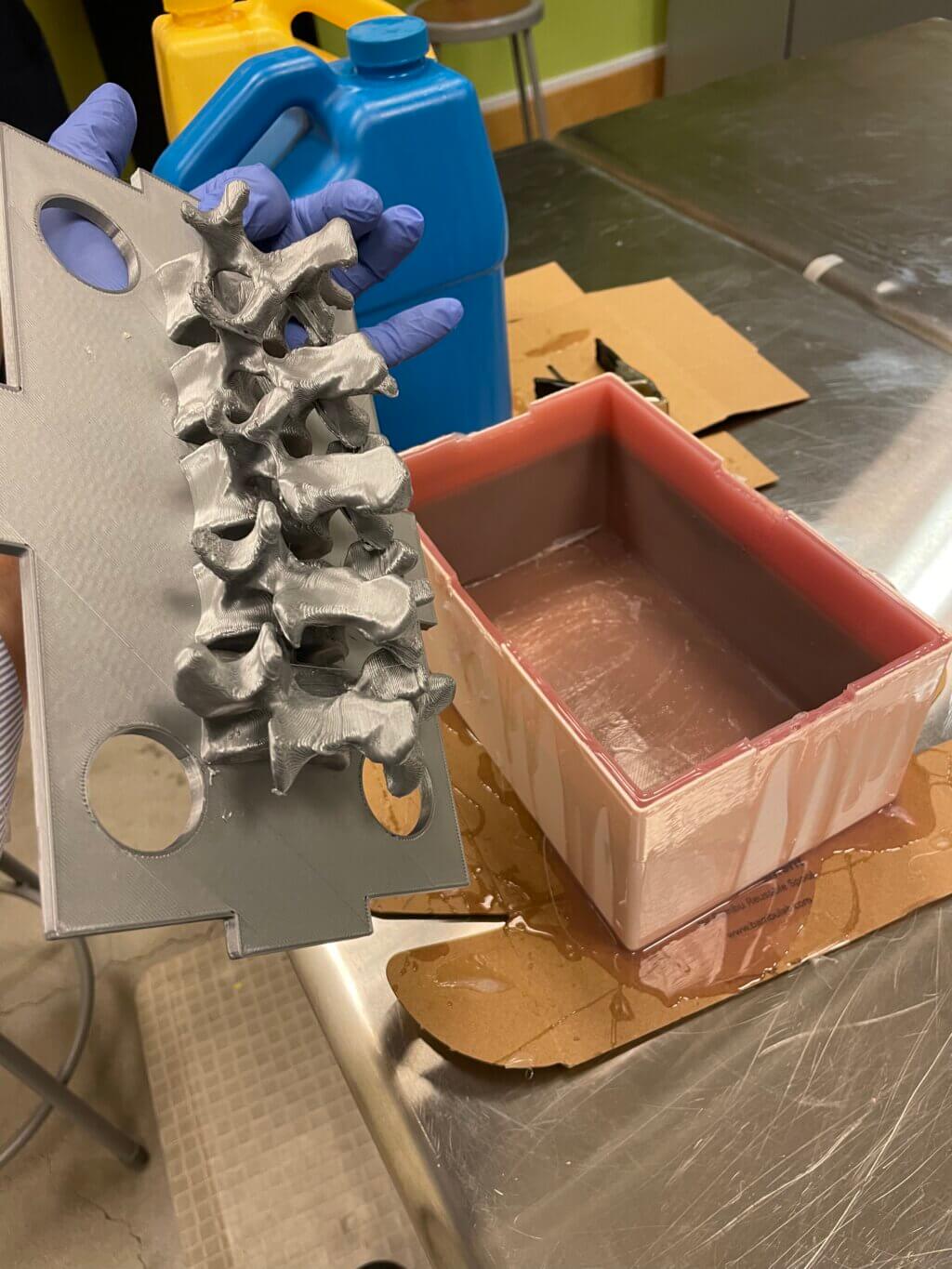

There’s so much that we would love to build. The hardest part is figuring out what the most important elements are and just building that. You have to start somewhere! We were unsure where to begin with prototyping. Thankfully, the Makers Lab at UCSF is a wonderful resource available to the UCSF campus and we were able to rapidly print iterative prototypes. Scott helped us refine 3D prints with difficult geometries.

We also requested Scott to rapidly design and manufacture an affordable (~$20), imageable lumbar puncture simulator box so we could test out NeedleGPS and compare it with another simulator that is available within the department (estimated cost $3,000-$5,000). That phantom Scott made is excellent and has been very helpful for our testing. The silicone and foam make a much more realistic feel with inserting needles.

Q: What was your favorite part of the process?

By far the best part is seeing the finished product and being able to hold it in your hands.

Q: What do you want to make next?

We’re excited to explore how much smaller and lighter we can make NeedleGPS!